Sumitomo C4 Separation

Process

11 licenses awarded, including:

Draw out full potential

of your mixed-C4

Did you know that there are simple ways to

maximize its value?

It is too often the case that mixed-C4s from the naphtha crackers are not being utilized to their full potential.

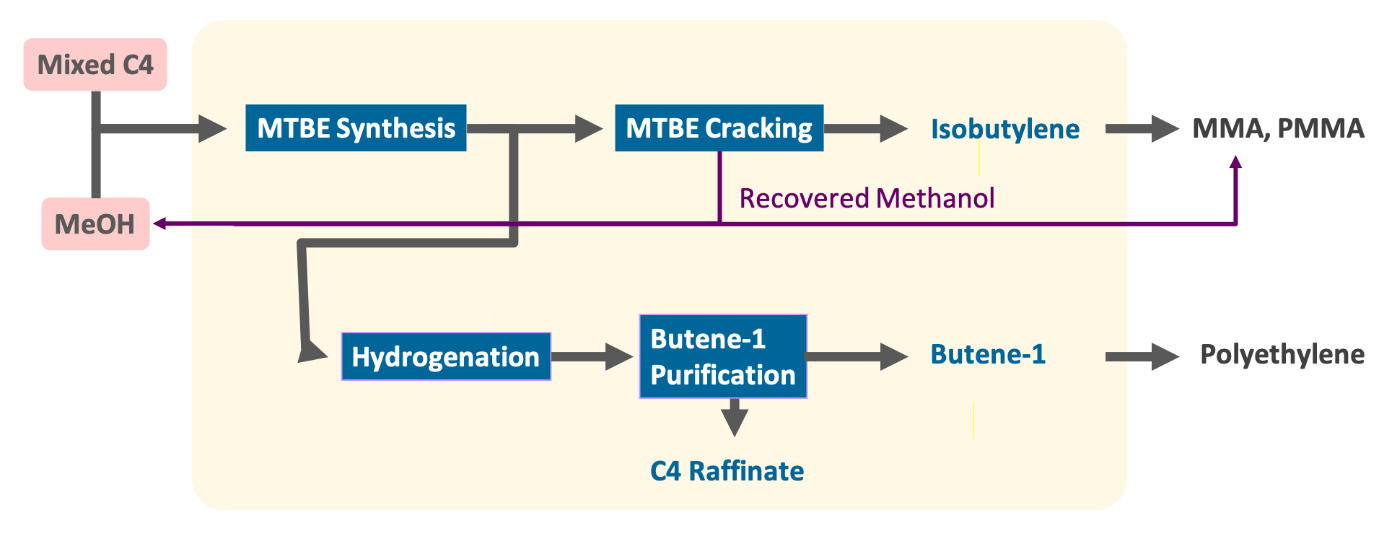

They are often returned back to the cracker or even burnt in the absence of the efficient separation technology such as ours. This is because in order to utilize the desired components such as isobutylene and 1-butene, they first need to be separated, but their boiling points being so close to each other, it is practically impossible to separate them by distillation.

With our separation process, you can zero in on your target components and pick them out by simple chemistry.

So that you can utilize them to take your product portfolio up higher with Sumitomo C4 Separation technology.

How?

Pick n’ mix from our set of

simple technologies

We have a full set of technologies to let you build your optimal configuration in a streamlined way.

Our portfolio not only allows you to separate and pick-out your desired C4, but also to mix and match flexibly from the full set of technologies to find the configuration best suited for you.

- But sounds like too much trouble?

- Be assured. Each of our technologies are simple and streamlined such that there are no special requirements, including those on equipment design and construction materials. That, plus our proprietary catalyst with a remarkably long life ensures that you can utilize your mixed-C4 and materialize your ideal product line-up with minimum capital and efforts.

You can rely on the fact that these set of processes were developed to fulfill our own needs as an owner of several integrated petrochemical complexes and have been in use for over multiple decades.

The “Three Elements of Trust”

in Sumitomo C4 Separation Process

-

Operational Excellence

- Your Competitive Edge:

- Rely on stable operation and minimize your operational loss

- No safety incidents in all licensed plants for decades since their start-up.

- Easy & simple operation with high reputation from licensees’ plant operators.

Click the image to enlarge -

Top Quality Product

- An Assurance You can Trust:

- Obtain high purity C4 components that can be applied even for those applications where stringent purity control is required.

- Proven and trusted quality meeting customer requirements since 1982

Click the image to enlarge -

Sustainability

- Your Long-Term Benefits:

- Maximize your ROI while getting one step closer in achieving your SDGs by minimizing waste

- You can expand your product portfolio by drawing out full potential of the components ready at hand.

Click the image to enlarge

Global Trust and Recognitions

The first commercialization of this process dates back to 1982.

Our experience as the owner of integrated complexes covering from refinery to high-end niche products have lead us to develop this process with the aim to utilize all components available from naphtha, an alchemy made possible by the proprietary made-in-Japan catalyst.

Through several decades of operation and numerous licenses worldwide, the process has a proven history of opening up doors of possibilities to expand your product portfolio.