Sumitomo EVA/LDPE Process

Swing Production of Ethylene-Vinyl Acetate and Low-Density Polyethylene

11 licenses awarded, including:

Stay Confident Under EXTREME Pressure!

Did you know that operation stability does not come as a matter of course, especially for LDPE/EVA plants?

This is because the reaction is carried out under extremely high pressure (more than double the pressure at the bottom of Marianas Trench!) where the fluids become super-critical.

Ask anybody with an experience in LDPE/EVA production and you will find that unscheduled shutdowns due to phenomenon called “decomposition” are fairly frequent, but not when you use Sumitomo EVA/LDPE technology. Our plant can run for over several decades without ever experiencing a decomposition, an outstanding record being second to none out of all LDPE/EVA processes. With our process, you can be confident that your plant will run as you planned, as if it was a matter of course.

EVA/LDPE is used for higher value added products such as food packaging, sport gears and solar panels.

With Sumitomo process, you can decide on the capacity flexibly from small to large, to utilize your ethylene most efficiently.

How?

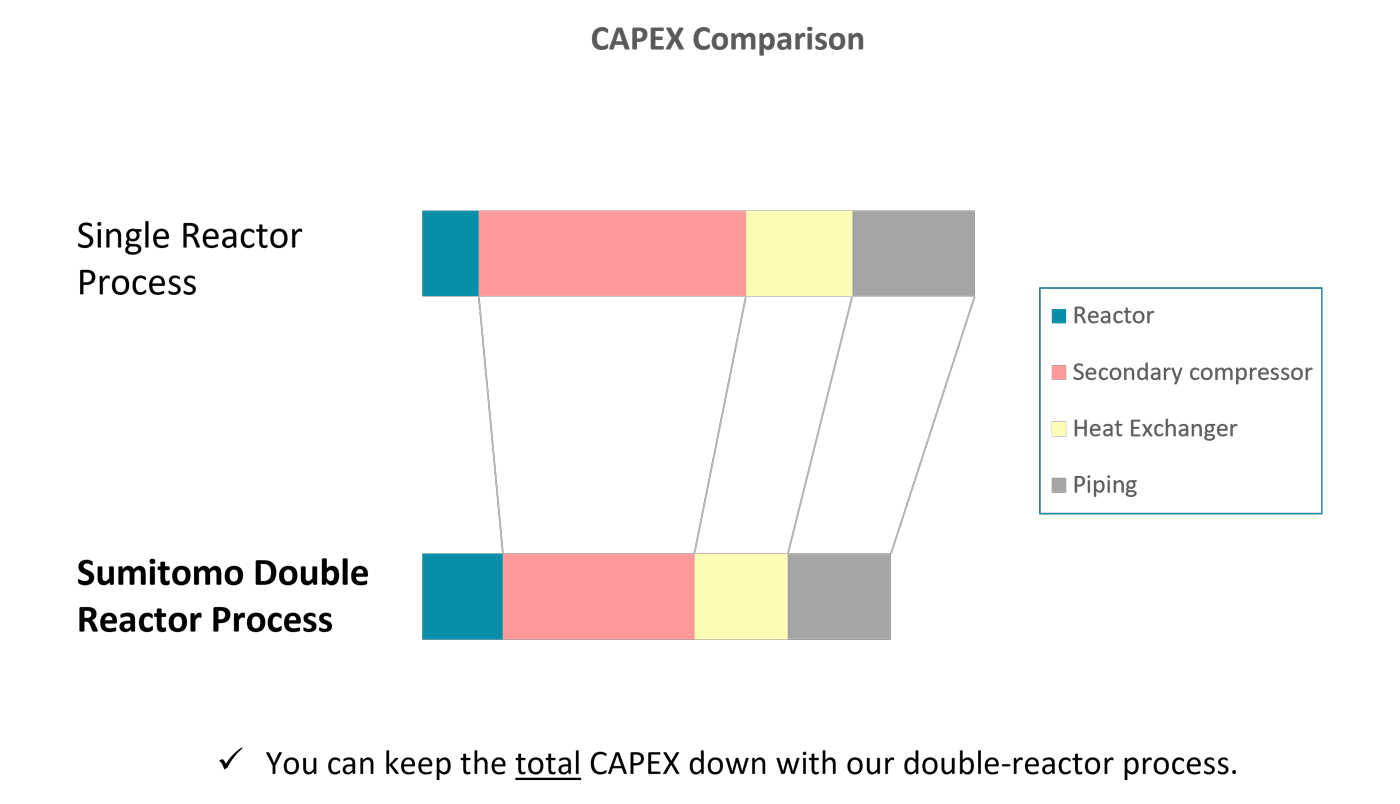

More is Less with Sumitomo’s Double Reactor System

The secret to the exceptional stability of Sumitomo process lies in its proprietary double reactor system.

Out of all processes, our process is the only one with double reactor system.

By having MORE reactors, the reaction condition can be made somewhat milder, resulting in stable operation.

- Cost is less, too

-

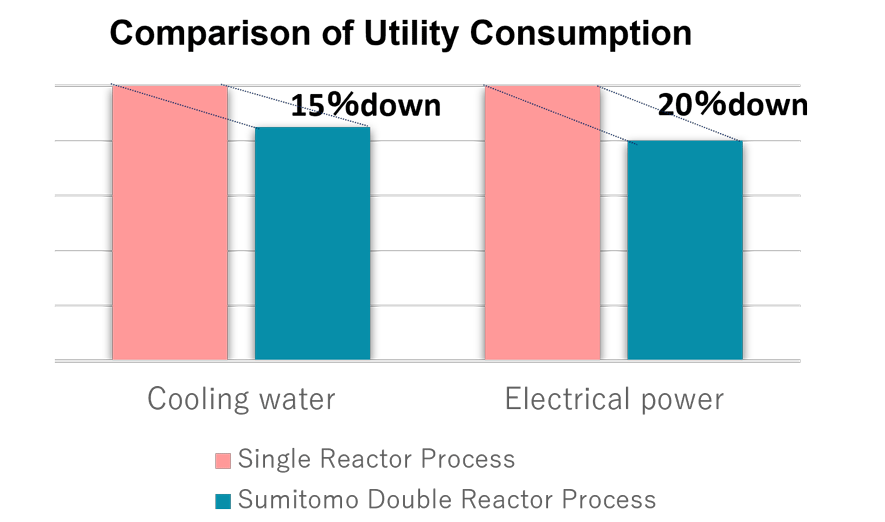

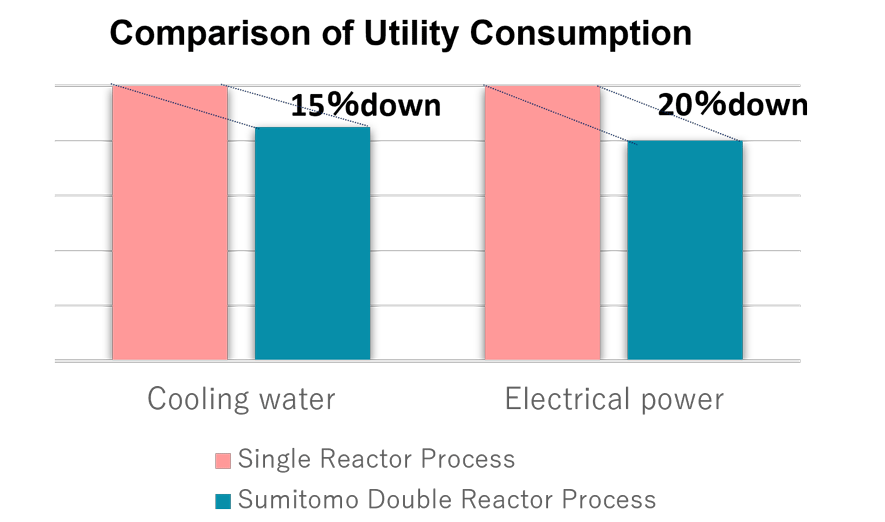

What’s more, the double reactor system also leads to reduction in feedstock and energy consumption.

- But sounds expensive?? Believe it or not, total investment cost is also less even with the double reactors due to the reduced capacity requirement for super-high-pressure (SHP) equipment.

To summarize, with MORE reactors, you enjoy: EXCEPTIONALLY LESS unplanned shutdown, LESS operation cost, AND LESS investment cost.

More is less, and of course, less is more, with Sumitomo Double reactor Process, where you can minimize your loss and maximize the profit.

The “Three Elements of Trust”

in Sumitomo EVA/LDPE Process

-

Operational Excellence

- Your Competitive Edge:

- Minimize your OPEX by minimizing operational loss.

- Compared to other processes, our process has remarkably less incidents of decomposition*

- Highly reputed by our licensees for its operability and stability compared to other EVA/LDPE processes

Click the image to enlarge *Decomposition: An emergency purge of super high pressure reaction mixture from reactors.

Once it happnes, the plant has to be stopped for some days for maintenance and searching root causes of the decomposition. -

Top Quality Product

- An Assurance You can Trust:

- You can produce proven and trusted products meeting customer requirements across the globe for over half-a-century.

Both EVA and LDPE produced can be utilized for any applications know in the market

- Less residue formation compared to other processes means products can be applied for lamination grade

- Low to High EVA content

Click the image to enlarge -

Sustainability

- Your Long-Term Benefits:

- Get one step closer in achieving your SDGs

Reduce your OPEX by almost 20%

- Up to 20% reduction in utility and power consumption compared to conventional processes

Click the image to enlarge

Global Trust and Recognitions

The first commercialization of this process dates back to 1958. Since then, we have been supplying our clients world-wide through our production facilities in Japan, Singapore and Saudi Arabia.

Through 11 licenses awarded thus far, we have gained an unswerving confidence on the operability, stability and safety of our process and we continue to spread the confidence through further licenses.