Sumitomo

Methyl Methacrylate Process

8 licenses awarded, including:

Start agile and stay ahead

with cracker-independent MMA process

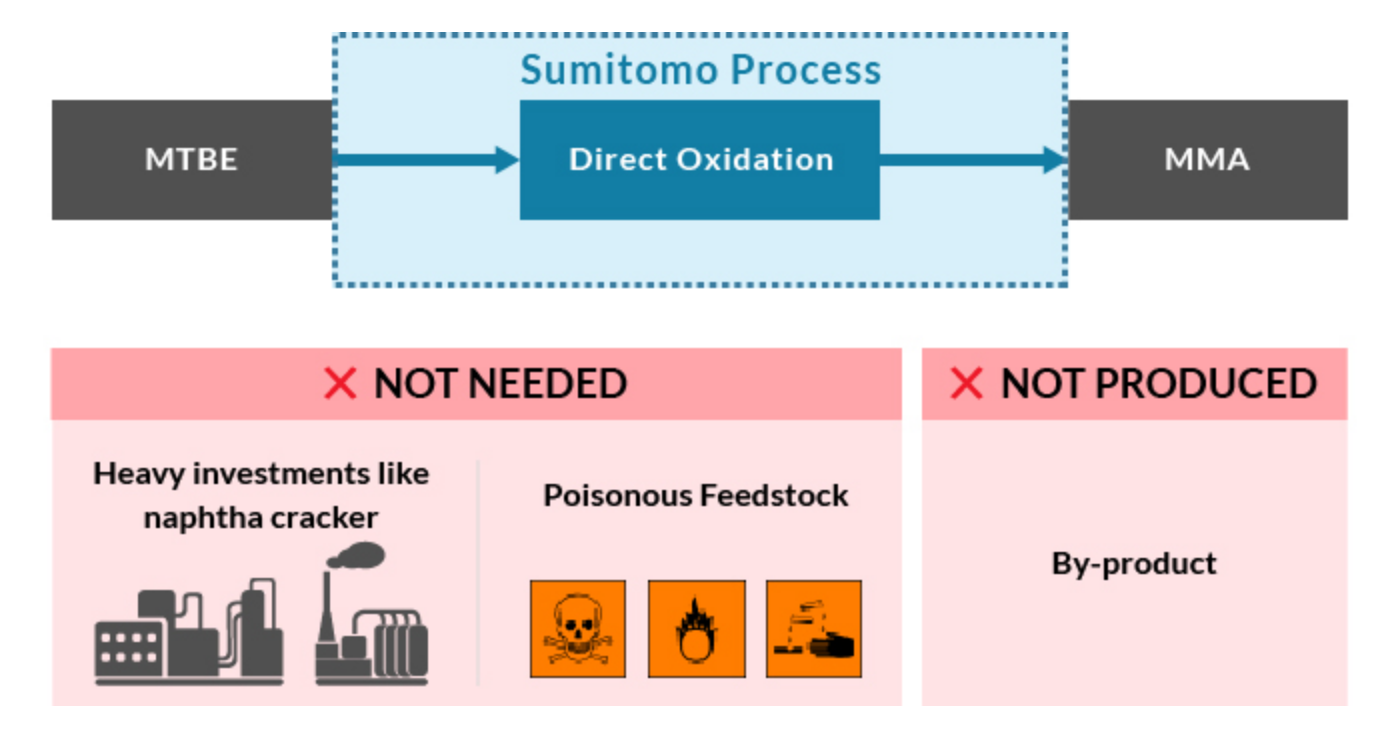

In many cases, MMA production starts with olefins from crackers, and you may think that you need to be located near crackers. Not so with our process. Developed in collaboration with NIPPON SHOKUBAI CO., LTD. our process lets you convert MTBE, readily and increasingly available from the market, to MMA in the most streamlined manner in presence of a proprietary catalyst.

All you need is MTBE and our license package to kick-start your MMA business and stay ahead of the curve.

How?

Versatility Meets Agility via Direct Route to MMA

Unlike other process that requires extremely poisonous feedstock and thus a heavy investment, our process only uses MTBE, which is easily transported and handled. With lighter asset and readily available feedstock, you can select your location flexibly and kick-start your MMA production.

In our process, MTBE is first cracked into isobutylene and methanol, which are then reacted together to form MMA – with a closed loop recovery of methanol, and without any by-product, you can produce MMA in the most streamlined way.

MTBE is produced in very large quantities worldwide and is almost exclusively used as a fuel additive in motor gasoline in many countries. Due to tightening of environmental regulations and transition to electronic vehicles, we believe that MTBE will become increasingly available in surplus in years to come.

With our versatile process, you can dive into MMA market with utmost agility and stay ever focused.

The “Three Elements of Trust”

in Sumitomo MMA Process

-

Operational Excellence

- Your Competitive Edge:

- Rely on stable operation and minimize your operational loss

- No safety incidents in all licensed plants for decades since their start-up.

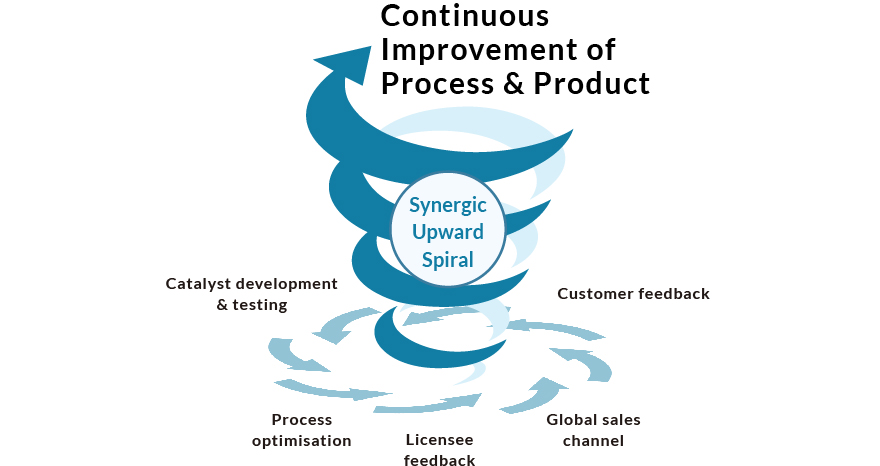

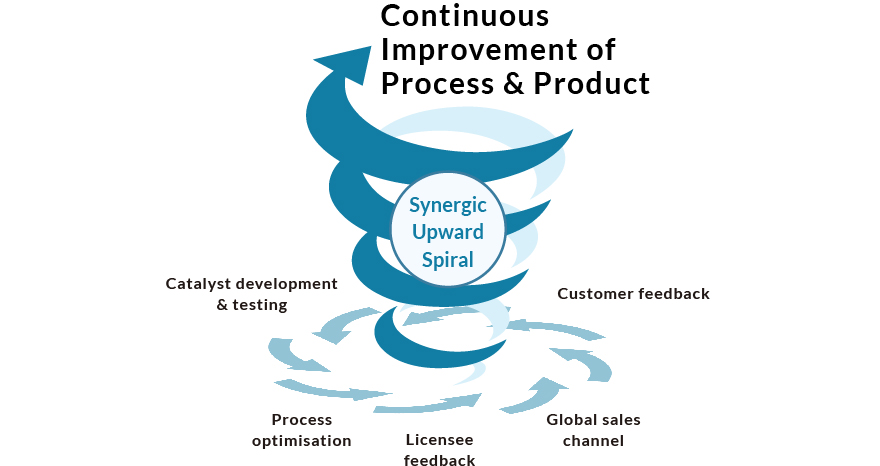

- Continuous R&D on the catalyst ensures improvements for the lifetime of your asset.

Click the image to enlarge -

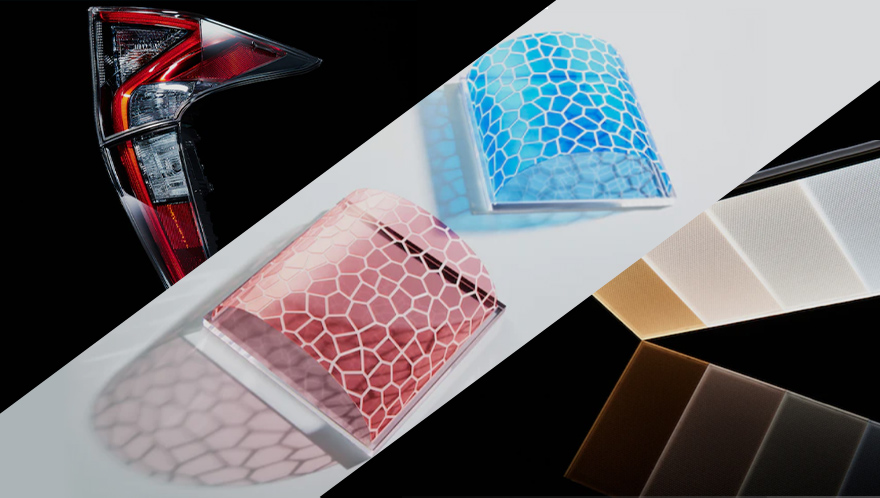

Top Quality Product

- An Assurance You can Trust:

- Always be assured of the best-quality MMA applicable even for high-quality PMMAs for optical applications.

- Stable production of high quality MMA

- Proven and trusted quality meeting customer requirements since 1982 through continuous improvements

Click the image to enlarge -

Sustainability

- Your Long-Term Benefits:

- Minimize your OPEX while getting one step closer in achieving your SDGs by minimizing energy consumption

- Our process utilizes the heat of reaction to generate steam, minimizing steam consumption.

Click the image to enlarge

Global Trust and Recognitions

The first commercialization of this process dates back to 1982. The MMA production methods utilizing MTBE or its precursor, mixed C4 components, originated in Japan. It is deeply routed in Japanese culture to try to put full value of all resources available to us to good use and to feel great regret if we cannot. It was too often the case that mixed-C4s from the naphtha crackers were not being utilized to their full potential due to the boiling points of the components being so close to each other. We have developed a set of technologies to utilize such components to maximize their value, and further, made it possible for anybody to enter into MMA business by starting from MTBE, which is readily available from the market.

Gain independence from naphtha complex and establish the most streamlined MMA business with our license.