Sumitomo Methyl Methacrylate Process

8 licenses awarded, including:

Make the most out of

your C4s at minimal effort

Have surplus C4s that you do not know what to do with?

– We have a solution.

As you know, mixed-C4s from the naphtha crackers are often returned back to the cracker to be converted to other olefins, or even burnt off in some cases. This is because in order to utilize the desired components, they first need to be separated, but their boiling points being so close to each other, it is practically impossible to separate them by distillation.

Our simple and safe process, developed in collaboration with NIPPON SHOKUBAI CO., LTD. lets you fully utilize your C4s by converting them to high value added methyl methacrylate (MMA) with minimal effort.

With Sumitomo MMA process, you can expand your business portfolio by fully leveraging your existing resources.

How?

Pioneering an Easy & Direct Route to MMA

We have a full set of technologies to let you establish your optimal C4 product chain.

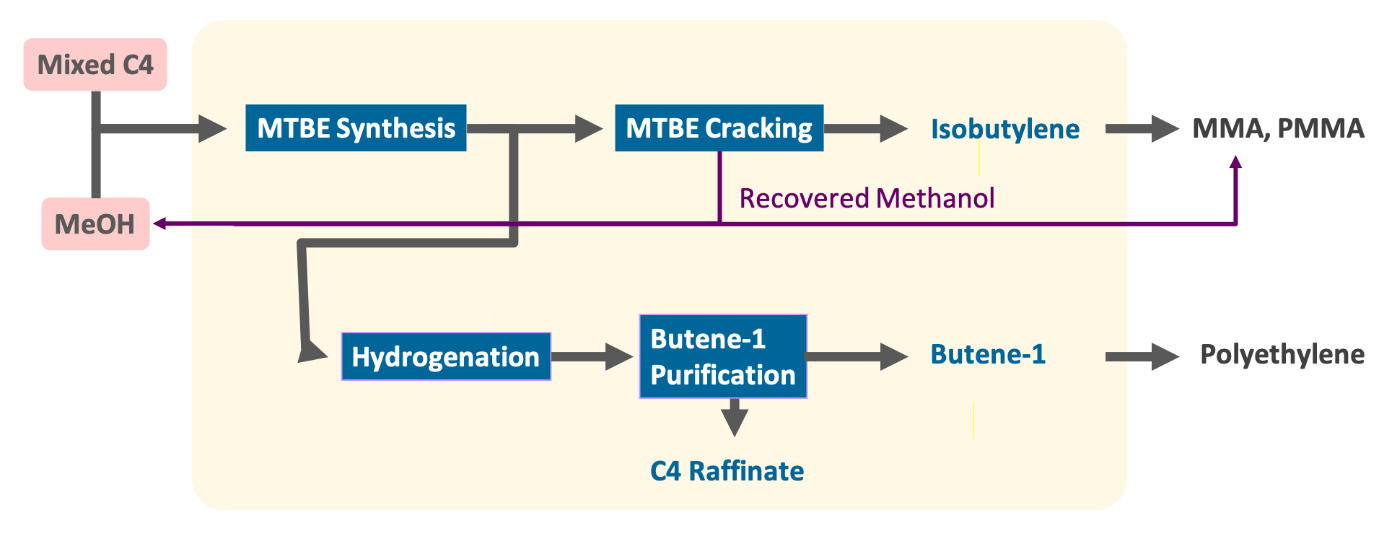

One of these is MMA production by extracting isobutylene from your mixed C4s via MTBE synthesis. Isobutylene is then reacted with methanol which is recovered from the process of isobutylene production by MTBE cracking.

- Have you heard of the Japanese term “Mottainai”?

- It is a Japanese expression of regret at the full value of resources not being put to their best use. It is deeply routed in our culture to feel great appreciation and to make full use of all resources that are available to us, and to feel regret if their full value is not being put to good use. The MMA production methods from C4s are originated in Japan based on such spirit, and Japanese technologies still hold as much as 80% share among global MMA production technologies by C4s, with Sumitomo Chemical technology among the highest.

Beside letting you leverage your resources fully, another characteristic of this MMA process is its simplicity.

As you know, conventional MMA requires the use of extremely poisonous hydrogen cyanide (HCN). As HCN cannot readily be transported, an HCN producing plant, often an acrylonitrile plant that byproduces HCN, needs to be integrated with the MMA plant, requiring heavy investment and stringent hazardous materials management. Sumitomo’s direct oxidation process has eliminated the use of hazardous materials and only uses safe feedstock widely available from the market, requiring minimum facilities and resources.

Further, our process has eliminated ammonium sulphate byproduct that is produced in substantial amount in the conventional process.

With our process, you can streamline your operations and focus on your core MMA business.

The “Three Elements of Trust”

in Sumitomo MMA Process

-

Operational Excellence

- Your Competitive Edge:

- Rely on stable operation and minimize your operational loss

- No safety incidents in all licensed plants for decades since their start-up.

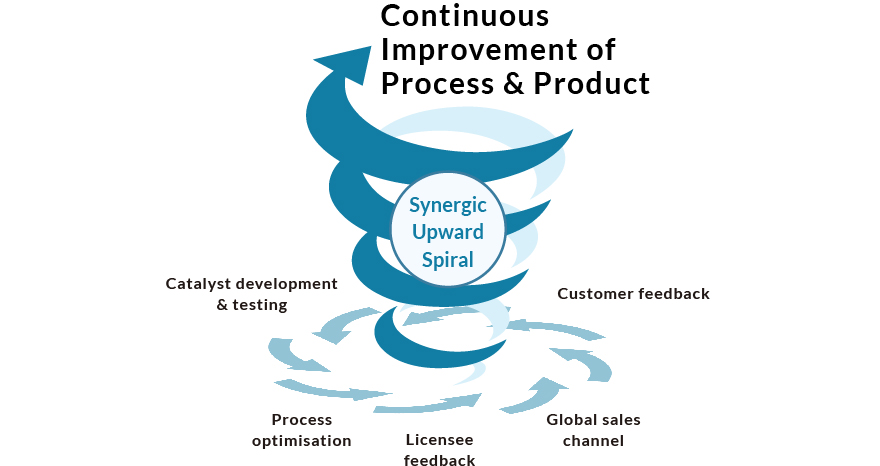

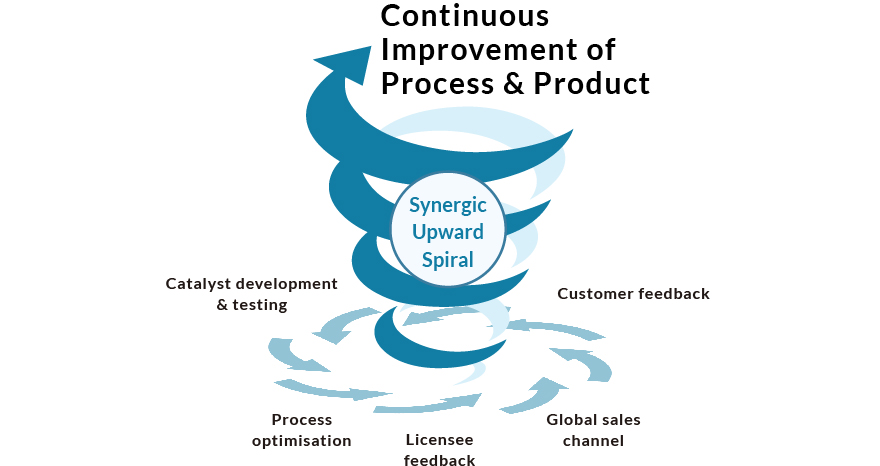

- Continuous R&D on the catalyst ensures improvements for the lifetime of your asset.

Click the image to enlarge -

Top Quality Product

- An Assurance You can Trust:

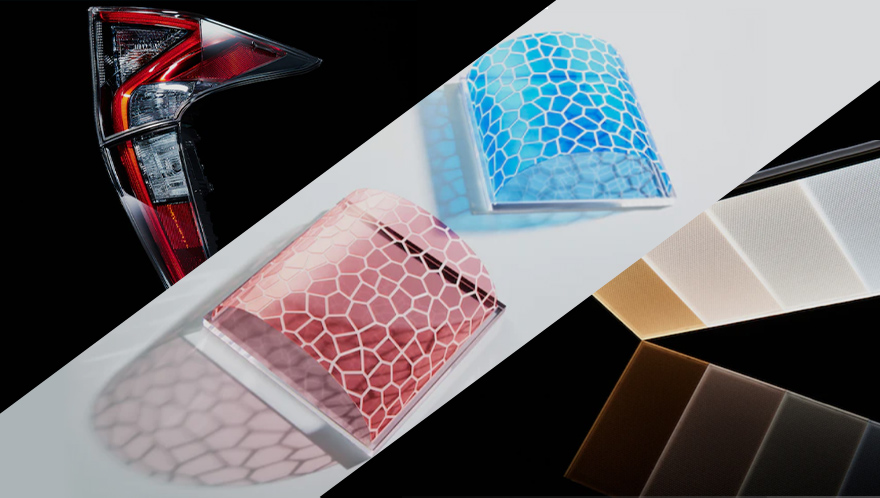

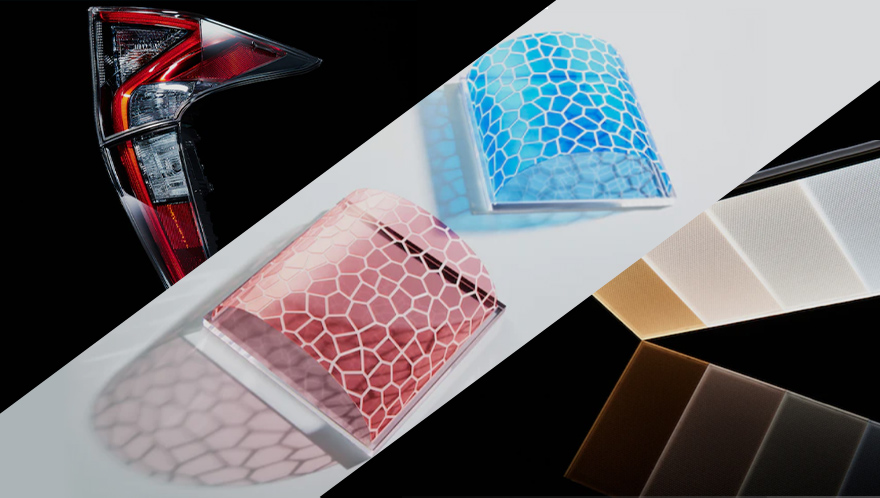

- Always be assured of the best-quality MMA applicable even for high-quality PMMAs for optical applications.

- Stable production of high quality MMA

- Proven and trusted quality meeting customer requirements since 1982 through continuous improvements

Click the image to enlarge -

Sustainability

- Your Long-Term Benefits:

- Minimize your OPEX while getting one step closer in achieving your SDGs by minimizing energy consumption

- Our process utilizes the heat of reaction to generate steam, minimizing steam consumption.

Click the image to enlarge

Global Trust and Recognitions

The first commercialization of this process dates back to 1982. The MMA production methods utilizing C4 components originated in Japan. It is deeply routed in Japanese culture to try to put full value of all resources available to us to good use and to feel great regret if we cannot. So, we developed a set of technologies to utilize such components to maximize their value. Japanese technology still holds as much as 80% share among global MMA production technologies by C4s, with Sumitomo Chemical technology among the highest.

Turn your resources at hand to gold with this alchemy achieved by made-in Japan high performance catalyst.