- Product Info

- SUMIKAEXCEL PES

- Features

Features of SUMIKAEXCEL PES

Introduction

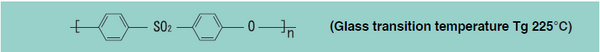

SUMIKAEXCEL PES (short for Polyethersulfone) is an amorphous heat-resistant resin produced domestically under license from ICI, and has the following molecular structure.

Figure 1-1-1 Chemical structure of PES

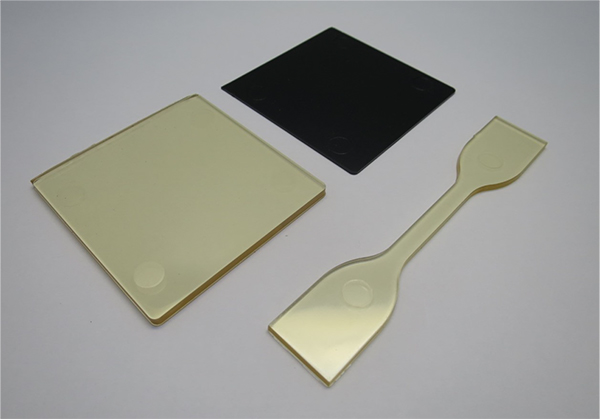

SUMIKAEXCEL PES is an amber-colored transparent resin that is characterized by heat resistance, creep resistance, dimensional stability, flame retardancy, and hot water resistance. As a molding material, it is used in a wide variety of applications, including electronic components such as relays and burn-in sockets, IC trays, printer and copier parts, medical equipment parts and dental supplies that require sterilization, and film for pagers and LCD boards.

We also offer powder grades, which are used in a wide range of applications, such as toughening agents for epoxy composite materials in aircraft, heat-resistant paints, adhesives, and flat and hollow fiber membranes for medical and food applications.

Figure 1-1-2 Photo of PES molded product

SUMIPLOY is a highly functional, highly heat-resistant polymer alloy compound based on super engineering plastics such as SUMIKASUPER, polyethersulfone, and polyetheretherketone, which utilizes the technology we have cultivated and accumulated over many years.

SUMIPLOY E is a sliding material whose main components are heat-resistant polyethersulfone (PES) and SUMIKASUPER E101. Among all the sliding materials that can be injection molded, it has the highest level of sliding properties (low and stable friction coefficient in dry conditions, high limit PV value), and is also characterized by its resistance to damage even when the mating material is a soft metal such as SUS or aluminum.

SUMIPLOY S is a sliding material based on PES that has been given sliding properties while maintaining the mechanical and thermal properties of PES. It is suitable for applications that require a certain degree of mechanical strength under relatively mild sliding conditions (low PV value).

SUMIPLOY K is a sliding material based on polyether ether ketone (PEEK). It is a material that has been given sliding properties while maintaining the excellent chemical resistance, fatigue resistance, radiation resistance, and heat resistance inherent to PEEK. It is suitable for use under harsh conditions such as high temperature and high load.

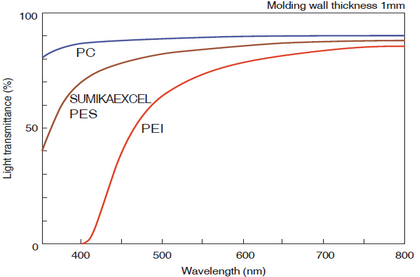

Light transmittance

It has an excellent level of light transmittance among heat-resistant engineering plastics.

Figure 1-1-3 Light transmittance of SUMIKAEXCEL PES

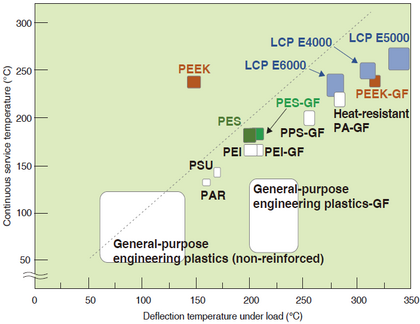

Heat-resistant

Figure 1-1-4 Continuous use temperature and deflection temperature under load (load 1.82 MPa)

Features of SUMIKAEXCEL and SUMIPLOY

Table 1-1-1 Features of SUMIKAEXCEL and SUMIPLOY

| SUMIKAEXCEL | SUMIPLOY |

|---|---|

|

|