- Product Info

- SUMIKASUPER™ E101

SUMIKASUPER™ E101

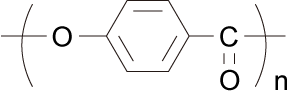

The SUMIKASUPER E101 series, a fully aromatic polyester resin, has outstanding abrasion resistance, self-lubricating properties, chemical resistance, and heat resistance.

Adding SUMIKASUPER E101 to solid lubricants such as polytetrafluoroethylene (PTFE) and graphite gives the material wear resistance and compression creep resistance, improving sliding properties.

Chemical structure

E101 Series

| E101-P | E101-M | E101-S | |

|---|---|---|---|

| Median particle size (μm) | 72 | 27 | 19.5 |

| Bulk density | 0.54 | 0.47 | 0.42 |

| Heat loss (5 hours) (%) | 0.9 | 0.9 | 0.9 |

These are measured values using Sumitomo Chemical's analytical methods.

The values are for reference only and are not guaranteed.

E101/PTFE general properties

| unit | E101/PTFE 20/80wt% |

E101/PTFE 30/70wt% |

Glass fiber/PTFE 25/75wt% |

Carbon fiber/PTFE 25/75wt% |

|

|---|---|---|---|---|---|

| Specific gravity | - | 1.95 | 1.84 | 2.24 | 1.93 |

| Tensile strength | MPa | 17 | 11 | 21 | 18 |

| Tensile elongation | % | 290 | 230 | 310 | 70 |

| Compressive strength | |||||

| 0.2% offset | MPa | 11 | 12 | 9 | 10 |

| 1% Deformation | MPa | 9 | 9 | 9 | 10 |

| 10% Deformation | MPa | 18 | 23 | 18 | 8 |

| 25% Deformation | MPa | 32 | 33 | 30 | 48 |

| Compressive modulus | MPa | 900 | 1,000 | 960 | 1,200 |

| Compression Creep | |||||

| 23℃, 14MPa, 24Hr | % | 4.2 | 2.1 | 7.7 | 1.7 |

| 100℃, 7MPa, 24Hr | % | 1.7 | 0.5 | 3.1 | 1.3 |

Sliding characteristics (versus SUS304)

| Wear coefficient K* | Friction coefficient μ | |

|---|---|---|

| E101/PTFE 30/70 |

1.2×10-5 | 0.20 |

| PTFE | 6,000×10-5 | 0.18 |

| GF/PTFE 25/75 |

16.7×10-5 | 0.29 |

| Graphite/PTFE 15/85 |

308×10-5 | 0.19 |

| Bronze/PTFE 30/70 |

17.4×10-5 | 0.23 |

| CF/PTFE 25/75 |

24.3×10-5 | 0.24 |

* (mm/km)/(kgf/cm2) Pressure P=6kgf/cm2, Speed V=40m/min, Measurement time: 7 hours

Sliding characteristics (against aluminum JIS5052)

| Wear coefficient K* | Friction coefficient μ | Amount of aluminum wear | |

|---|---|---|---|

| E101/PTFE 30/70 |

1.5×10-5 | 0.21 | Less than 0.1 mg |

| GF/PTFE 25/75 |

2,200×10-5 | 0.34 | 67.4mg |

| CF/PTFE 25/75 |

1,200×10-5 | 0.23 | 50.7mg |

* (mm/km)/(kgf/cm2) Pressure P = 10kgf/cm2, Speed V = 40m/min, Measurement time: 20 hours (E101/PTFE), 2 hours (others)

Heat deterioration resistance

| E101/PTFE 20/80 |

E101/PTFE 30/70 |

||

|---|---|---|---|

| Retention Rate (%) | Tensile strength | 97 | 94 |

| Tensile elongation | 104 | 95 | |

| Weight change (%) | -1.5 | -2.3 | |

| Dimensional change (%) | MD | -0.05 | -0.10 |

| TD | -0.06 | -0.12 |

E101/PTFE gasoline and engine oil resistance

| Gasoline resistance | Engine oil resistance | ||||

|---|---|---|---|---|---|

| E101/PTFE 20/80 |

E101/PTFE 30/70 |

E101/PTFE 20/80 |

E101/PTFE 30/70 |

||

| Retention Rate (%) | Tensile strength | 98 | 94 | 97 | 91 |

| Tensile elongation | 104 | 108 | 105 | 101 | |

| Weight change (%) | +1.06 | +0.62 | +0.41 | +2.02 | |

| Dimensional change (%) | MD | +0.55 | +0.56 | +0.15 | +0.40 |

| TD | +0.47 | +0.35 | 0 | +0.18 | |

The physical properties are measured using Sumitomo Chemical's analytical methods.

The values are for reference only and are not guaranteed.

The contents of this document are based on currently available materials, information, and data.

It may be subject to revision based on new findings.