- Product Info

- SUMI-EPOXY

SUMI-EPOXY

SUMI-EPOXY is a multifunctional epoxy resin that has high heat resistance, mechanical properties, low shrinkage, and chemical resistance.

We have SUMI-EPOXY ELM-434 series, which has four functional groups, and the ELM-100 series, which has three functional groups.

SUMI-EPOXY ELM-434 series

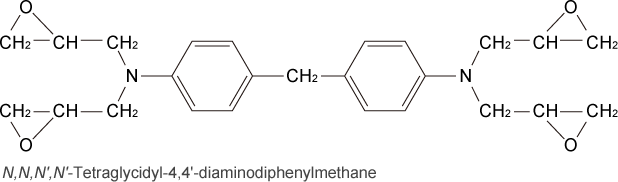

SUMI-EPOXY ELM-434 series is an amine-based tetrafunctional epoxy (tetraglycidyldiaminodiphenylmethane (TGDDM)).

It is used in CFRP, heat-resistant paints, heat-resistant adhesives, etc., and has a track record of being used in CFRP applications in the primary structures of aircraft.

We offer three grades with different viscosities: ELM-434, ELM-434L, and ELM-434VL. We can offer a grade that meets the needs of our customers, from high to low viscosity.

Chemical structure

Major features

- It has high heat resistance.

- It has excellent mechanical properties.

- It has excellent low shrinkage properties.

- It has excellent chemical resistance.

Physical properties *

| Item/Grade | ELM-434VL | ELM-434L | ELM-434 |

|---|---|---|---|

| Epoxy equivalent weight (g/eq) | 115 | 118 | 119 |

| Hydrolyzable chlorine (%) | 0.01 | 0.01 | 0.02 |

| Hue (Gardner) | 3 | 4 | 7 |

| Volatile content (%) | 0.07 | 0.18 | 0.03 |

| moisture(%) | 0.01 | 0.01 | 0.01 |

| Viscosity (mPa·s) 50℃* | 5,000 | 8,200 | 11,900 |

* Physical properties are measured using Sumitomo Chemical's analytical methods.

* Viscosity is measured using a Brookfield viscometer.

Cured properties of ELM-434

* Composition: Epoxy compound/4,4'-DDS=100/40phr

| Item | ELM-434 |

|---|---|

| Tg (℃) | 230 |

| Flexural strength (MPa) | 160 |

| Flexural modulus (GPa) | 3.5 |

| 5% weight loss temperature (Air) (℃) | 370 |

| Linear expansion coefficient (TMA compression) (ppm/℃) 2nd Run: 50-100℃ | 55 |

| Linear expansion coefficient (TMA compression) (ppm/℃) 2nd Run: 100-150℃ | 63 |

The values are for reference only and are not guaranteed.

The contents of this document are based on currently available materials, information, and data.

It may be subject to revision based on new findings.

SUMI-EPOXY ELM-100 series

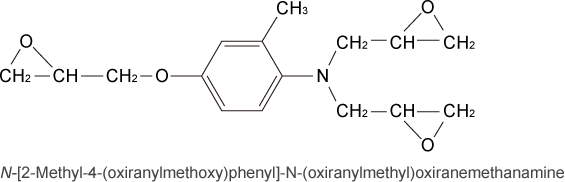

SUMI-EPOXY ELM-100 series is an amine-based trifunctional epoxy.

It is used in heat-resistant adhesives and paints for copper-clad laminates for printed wiring boards.

The ELM-100 series consists of two grades: ELM-100 and the low viscosity ELM-100H.

Chemical structure

Physical properties *

| Item | ELM-100H | ELM-100 |

|---|---|---|

| Epoxy equivalent weight (g/eq) | 104 | 107 |

| Total chlorine (ppm) | 1,400 | 3,600 |

| Non-volatile content (%) | 100 | 99.6 |

| Viscosity (mPa・s) 25℃ | 600 | 1,100 |

* Physical properties are measured using Sumitomo Chemical's analytical methods.

* Viscosity is measured using a Brookfield viscometer.

ELM-100 cured properties

* Composition: Epoxy compound/4,4'-DDS=100/40phr

| Item | ELM-100 |

|---|---|

| Tg (℃) | 260 |

| Flexural strength (MPa) | 160 |

| Flexural modulus (GPa) | 3.5 |

| 5% weight loss temperature (Air) (℃) | 355 |

| Linear expansion coefficient (TMA compression) (ppm/℃) 2nd Run: 50-100℃ | 60 |

| Linear expansion coefficient (TMA compression) (ppm/℃) 2nd Run: 100-150℃ | 68 |

The values are for reference only and are not guaranteed.

The contents of this document are based on currently available materials, information, and data.

It may be subject to revision based on new findings.