- PRODUCT

- ACRYFT™

PRODUCT

ACRYFT™

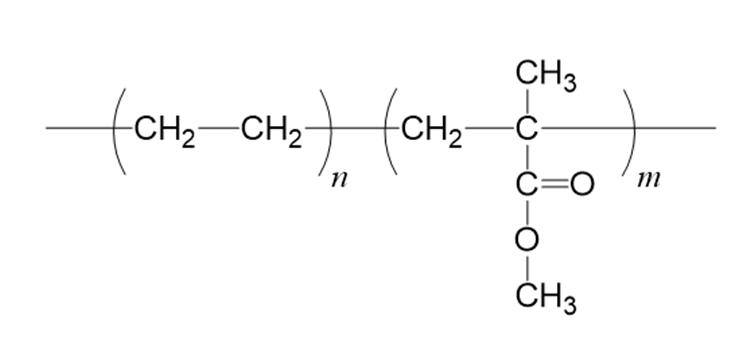

What is Acryft™?

Acryft™ is an ethylene-methyl methacrylate copolymer (EMMA).

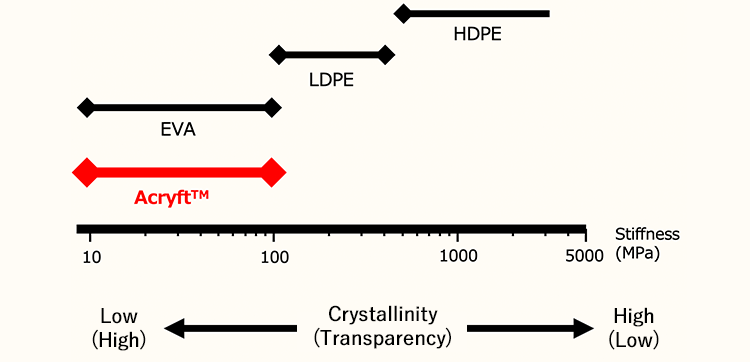

Acryft™ is as easy to process as LDPE and demonstrates higher softness and transparency.

-

1. Chemical structure of Acryft™

-

2. Stiffness comparison with commodity ethylene based polymers

Features of Acryft™

- Good thermal stability

- Easy processing same as LDPE

- Low corrosivity, VOC, and odor with no acid generation

- Higher level of softness and transparency

Grades

Acryft™ is available in a wide range of MMA content levels and MFR.

The values given are standard values and not to be considered as sales specifications or guaranteed values.

| Suitable applications and features | General purpose | For film/sheet | For extrusion lamination | Wires and cables | Hot-melt adhesives | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For modifiers | Soft matte film | |||||||||||||||

| Item | Test Method | Unit | WD106 | WK307 | WK402 | WD203-1 | WD201-F | WH206-F | CM-8013 | CM-8014 | WD301-F | WH303-F | WH401-F | WH102 | CM5021 | CM5022 |

| MMA Content | Sumitomo-Method | wt% | 5.8 | 25 | 25 | 5 | 10 | 20 | 12.5 | 17.5 | 10 | 18 | 20 | 17 | 28 | 32 |

| MFR | JIS K7210-1 *1 | g/10min | 0.32 | 7 | 20 | 2 | 2 | 2 | 3.5 | 4 | 7 | 7 | 20 | 0.25 | 450 | 450 |

| Density | JIS K7112 | kg/m3 | 920 | 940 | 940 | 920 | 930 | 940 | 930 | 940 | 930 | 940 | 940 | 930 | 940 | 950 |

| Tensile Strength | JIS K7113 *2 | MPa | 18 | 9 | 8 | 15 | 16 | 16 | 11 | 10 | 11 | 9 | 8 | 25 | 2 | 2 |

| Elongation | JIS K7113 *2 | % | 750 | 730 | 750 | 750 | 740 | 720 | 710 | 700 | 700 | 750 | 700 | 750 | 320 | 350 |

| Flexural Modulus | ASTM D747 | MPa | 80 | 17 | 15 | 88 | 65 | 20 | 60 | 32 | 65 | 27 | 17 | 35 | 8 | 6 |

| Durometor Hardness | JIS K7215 | A | 100 | 85 | 84 | 100 | 100 | 90 | 95 | 91 | 97 | 91 | 89 | 93 | 73 | 65 |

| D | 48 | 31 | 30 | 48 | 43 | 38 | 42 | 36 | 43 | 36 | 34 | 43 | 20 | 17 | ||

| Vicat Softening Point | JIS K7206 | ℃ | 85 | 47 | 45 | 83 | 75 | 60 | 65 | 60 | 75 | 60 | 50 | 73 | < 25 | < 25 |

| Melting Point | JIS K7121 | ℃ | 101 | 80 | 79 | 106 | 100 | 86 | 89/110 | 79/110 | 100 | 89 | 86 | 90 | 67 | 63 |

| R&B Softening Point | JIS K2207 *3 | ℃ | > 195 | 143 | 125 | 185 | 185 | 185 | 175 | 170 | 150 | 146 | 125 | > 195 | 90 | 89 |

| Brittle Temp. | JIS K7216 | ℃ | < -75 | < -75 | < -75 | < -75 | < -75 | < -75 | < -75 | < -75 | < -75 | < -75 | < -75 | < -75 | -46 | -46 |

| E.S.C.R. | ASTM D1693 *4 | hr | > 300 | > 300 | 50 | 5 | 50 | > 300 | 1 | > 300 | 1 | 80 | 13 | > 300 | < 1 | < 1 |

*1:190℃, 21.2N

*2:Test specimen No. 2 at a tensile speed of 500mm/min

*3:Ring & ball method by §6.4

*4:Environmental Stress Cracking Resistance / Bent strip method using IGEPAL CO-630 10% solution

Thermal stability

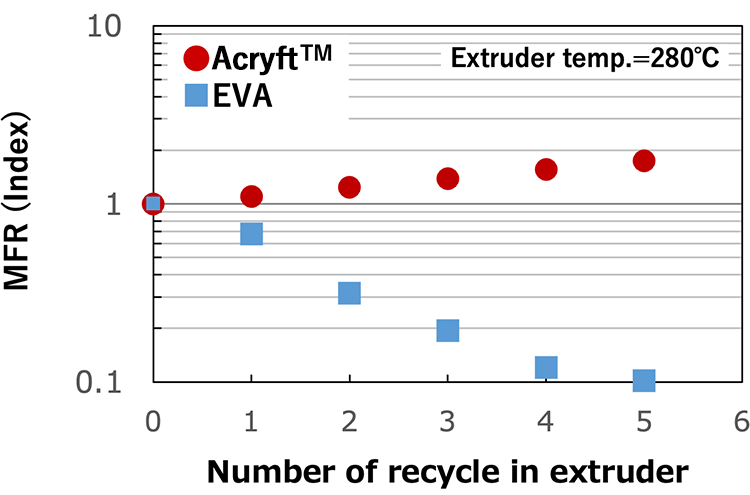

1. Recyclability

Acryft™ shows no increase in viscosity even during high-temperature processing and can therefore easily be recycled in extrusion processing.

2. Durability in high temperature processing

Comparison of scorched spots on extruder filters after continuous extrusion processing (Acryft™ vs. EVA)

-

Acryft™: Fewer scorched spots

-

EVA: More scorched spots

Acryft™ can be applied to long, continuous extrusion processing as it experiences less gelation under high-temperature processing.

Low corrosivity (no acid generation)

| Resin samples | 20% as co-monomer content |

|---|---|

| Test method | A resin sheet sample (thickness: 3mm) was put on an iron plate (size: 50×30×3mm) at 280℃ and 100kg/cm2 for 10min. Afterwards, the iron plate was removed from the resin sheet and placed under saturated water vapor at room temperature for 24hrs. |

-

Acryft™ No rust

-

EVA Rust

Acryft™ can be used safely for metal contact applications.

Easily peelable from rubber materials

Acryft™ is suitable for rubber wrapping film due to its low adhesion strength to rubber materials.

| Resin for film | Acryft™ | LDPE | EVA | EEA | |

|---|---|---|---|---|---|

| Co-monomer content (wt%) | 10 | - | 5 | 18 | |

| Peel strength between film and rubber (g/25mm) |

vs. butyl rubber | 165 | 450 | 480 | 500 |

| vs. EPDM rubber | 20 | 700 | 670 | 540 | |

Film thickness: 30μm

Pasting conditions (film and rubber): Load 10kgf/(150mm×150mm) at 80℃ for 2hrs

Peeling speed: 300mm/min

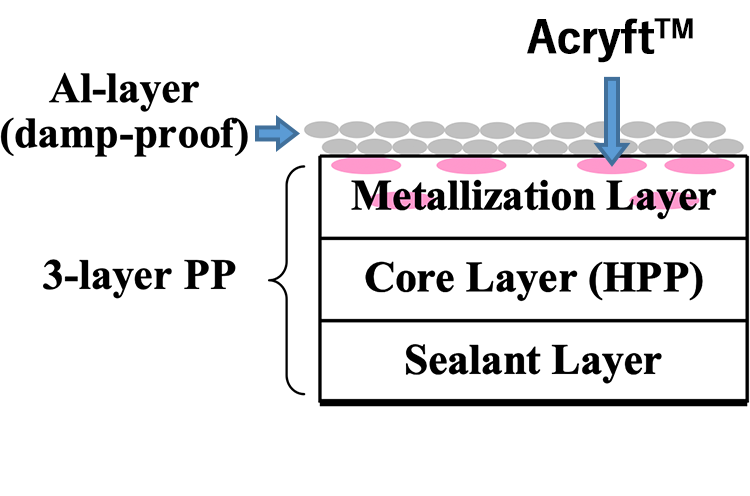

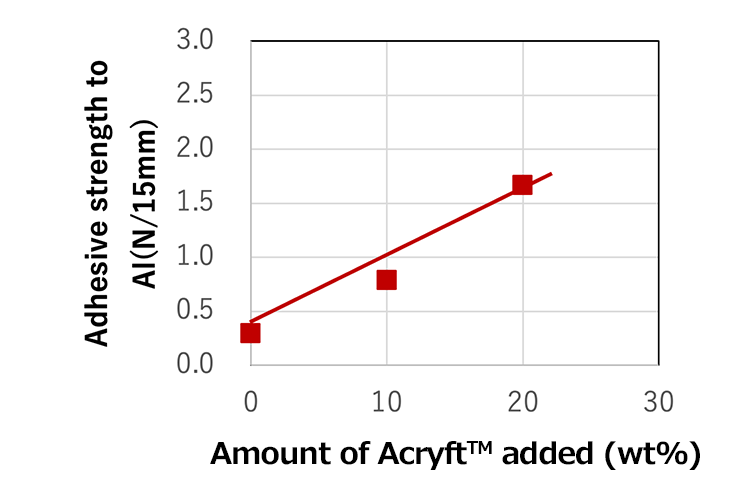

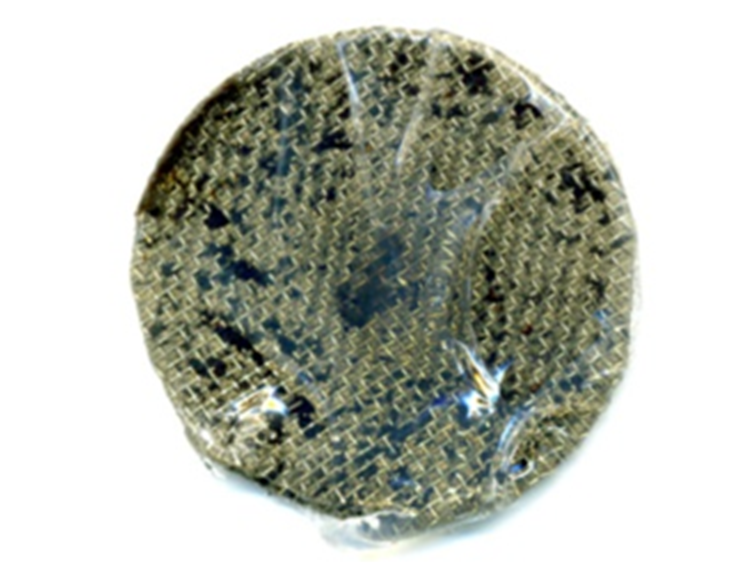

VMCPP application

Recommended amount of Acryft™ added to the metallization layer of CPP: 10-20wt%

Suitable grade: WH303-F or WH401-F

Acryft™ (showed in pink circle) is a useful material to improve bonding strength of VMCPP by dosing 10-20wt% to the metallization layer of CPP.

Extrusion lamination properties

Acryft™ shows superb bonding strength with several base layers compared with LDPE thanks to its extrusion lamination properties.

| Base layer (substrate) | Al | PET | O-Ny | PE | |

|---|---|---|---|---|---|

| Processing conditions | Extrusion temp. | 310℃ | 310℃ | 310℃ | 300℃ |

| Corona discharge treatment |

No | Yes | Yes | No | |

| Adhesive strength between substrate and laminated resin |

Acryft™ | 3.3 | 3.1 | 7.7 | > 10 |

| LDPE | 1.2 | 1.5 | 2.4 | 2.8 | |

Unit of adhesive strength in above table: N/25mm

* Layer structure: Substrate//laminated resin(40μm)

* Lamination speed: 80m/min

Features and suitable applications of Acryft™

| Features of Acryft™ | Useful properties of Acryft™ for each application |

Suitable applications |

|---|---|---|

| Chemical stability under higher temperatures | Less gel and fish-eye Recyclability |

Multilayer film with Engineering thermoplastic Modifier for VMCPP Extrusion lamination Hot melt adhesives |

| No acid generation Less VOC |

Less corrosivity Solution for sick building syndrome |

Plastic film for electric devices (Dicing die bonding film/protective film) Building materials |

| Polarity derived from the carboxylate ester group | Better bonding strength with substrates having higher polarity | Extrusion lamination |

| Highly branched molecular structure | Higher expansion ratio of foam | Automotive parts Foam products for interiors |

| Vibration-damping property | NVH (Noise, Vibration, Harshness) solution | Automotive interior parts |

| Softness | Maintaining softness after high filler loading | Sheath material for wires and cables Backing material for carpet |

| Hydrolysis resistance Light resistance |

Weatherability | Greenhouse film |

| Low melting temperature | Melting at lower temperatures | Melting bags |

| Film surface properties | Easy peelable from rubber material | Rubber wrapping film |