- PRODUCT

- EXCELLEN™ VL/FX

PRODUCT

EXCELLEN™ VL/FX

What is Excellen™ VL/FX?

Excellen™ VL and FX are ethylene-alpha olefin co-polymers.

Excellen™ VL shows good heat resistance and processability compared to other soft ethylene based plastomers.

Excellen™ FX shows good heat resistance and mechanical strength compared to other soft ethylene based plastomers.

| Excellen™ VL | Excellen™ FX | |

|---|---|---|

| Chemical structure |

|

|

| Catalyst for production | Ziegler-Natta catalyst | Metallocene catalyst |

| Characteristics |

|

|

Product Grades

1. Excellen™ VL

| Item | Test Method | Unit | VL100 | VL102 | VL200 | VL700 | EUL731 |

|---|---|---|---|---|---|---|---|

| MFR | JIS K7210-1 *1 | g/10min | 0.8 | 0.9 | 2 | 10 | 10 |

| Density | JIS K7112 | kg/m3 | 900 | 908 | 900 | 905 | 895 |

| Tensile Strength at Break | JIS K7161 *2 | MPa | 25 | 24 | 19 | 11 | 9 |

| Elongation at Break | JIS K7161 *2 | % | 900 | 900 | 900 | 900 | 900 |

| Flexural Modulus | ASTM D747 | MPa | 64 | 88 | 64 | 78 | 54 |

| Durometer Hardness | JIS K7215 | A | 90 | 93 | 90 | 92 | 88 |

| D | 42 | 46 | 42 | 43 | 37 | ||

| E.S.C.R. | ASTM D1693 *3 | hr | > 2000 | > 2000 | > 2000 | > 2000 | > 2000 |

| Tensile-Impact Energy | ASTM D1822-61T | KJ/m2 | 1050 | 1000 | 800 | 300 | 440 |

| Vicat Softening Temperature | JIS K7206 | ℃ | 70 | 83 | 67 | 68 | 52 |

| Melting Point | JIS K7121 | ℃ | 115 | 117 | 115 | 117 | 114 |

| Brittle Temp. | JIS K7216 | ℃ | < -75 | < -75 | < -75 | < -75 | < -75 |

| Features | Flexibility, Strength, Heat resistance | Strength, Heat resistance | Flexibility, Strength, Heat resistance | Heat resistance | Flexibility, Heat resistance | ||

| Recommended applications | Film, Extrusion, Modifier | Injection molding, Modifier | |||||

- The values given are standard values and not to be considered as sales specifications or guaranteed values.

*1 190℃, 21.2N

*2 Test specimen No. 2 at a tensile speed of 500mm/min

*3 Environmental Stress Cracking Resistance / Bent strip method using IGEPAL CO-630 10% solution

2. Excellen™ FX

| C6' Excellen™ FX | C4' Excellen™ FX | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Item | Test Method | Unit | FX201 | FX307 | FX402 | FX352 | FX555 | FX551 | FX558 |

| MFR | JIS K7210-1 *1 | g/10min | 2 | 3.2 | 8 | 4 | 16 | 30 | 75 |

| Density | JIS K7112 | kg/m3 | 898 | 890 | 880 | 886 | 878 | 880 | 890 |

| Tensile Strength at Break | JIS K7161 *2 | MPa | 47 | 48 | 32 | 25 | 3 | 4 | 4 |

| Elongation at Break | JIS K7161 *2 | % | 600 | 650 | 710 | 730 | 640 | 730 | 640 |

| Flexural Modulus | ASTM D747 | MPa | 49 | 26 | 11 | 15 | 5 | 11 | 23 |

| Durometer Hardness | JIS K7215 | A | 87 | 83 | 77 | 76 | 67 | 71 | 76 |

| D | 40 | 33 | 23 | 31 | 20 | 26 | 34 | ||

| E.S.C.R. | ASTM D1693 *3 | hr | > 2000 | > 2000 | > 2000 | > 1000 | > 1000 | > 1000 | 23 |

| Tensile-Impact Energy | ASTM D1822-61T | KJ/m2 | 2800 | 2580 | 1350 | 710 | 200 | 200 | 180 |

| Vicat Softening Temperature | JIS K7206 | ℃ | 85 | 65 | 47 | 51 | 28 | 34 | 41 |

| Melting Point | JIS K7121 | ℃ | 94 | 83 | 68 | 70 | 53 | 66 | 79 |

| Brittle Temp. | JIS K7216 | ℃ | < -75 | < -75 | < -75 | < -75 | < -75 | < -75 | < -75 |

| Features | Strength, Flexibility | Strength, Flexibility | low-temp. sealability | Flexibility | Contains filler | Flexibility | High fluidity | ||

| Recommended application | Film | Film | Film, Lamination | Film, Modifier | Injection molding, Modifier | Modifier | Modifier | ||

- The values given are standard values and not to be considered as sales specifications or guaranteed values.

*1 190℃, 21.2N

*2 Test specimen No. 2 at a tensile speed of 500mm/min

*3 Environmental Stress Cracking Resistance / Bent strip method using IGEPAL CO-630 10% solution

Features of Excellen™ VL

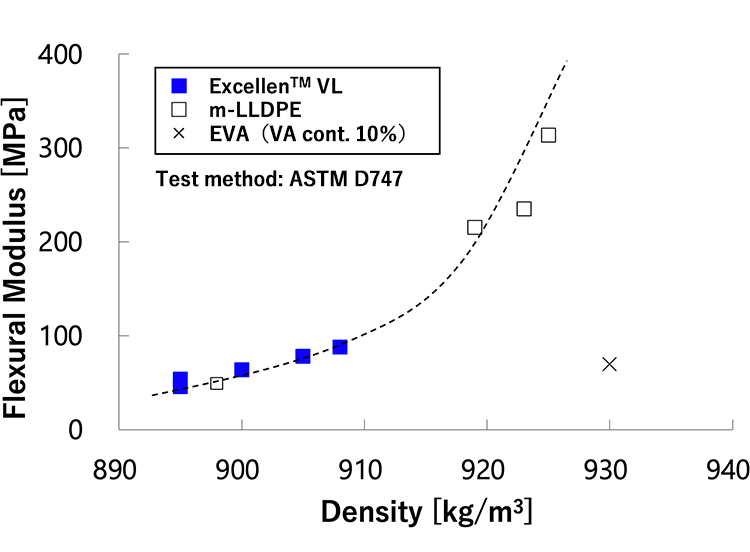

1. Flexibility

Excellen™ VL shows excellent flexibility due to its low density and low crystallinity

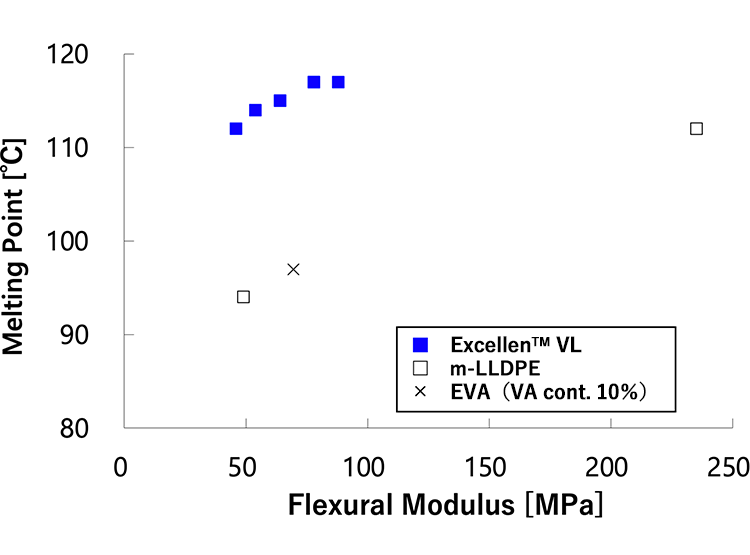

2. Heat resistance

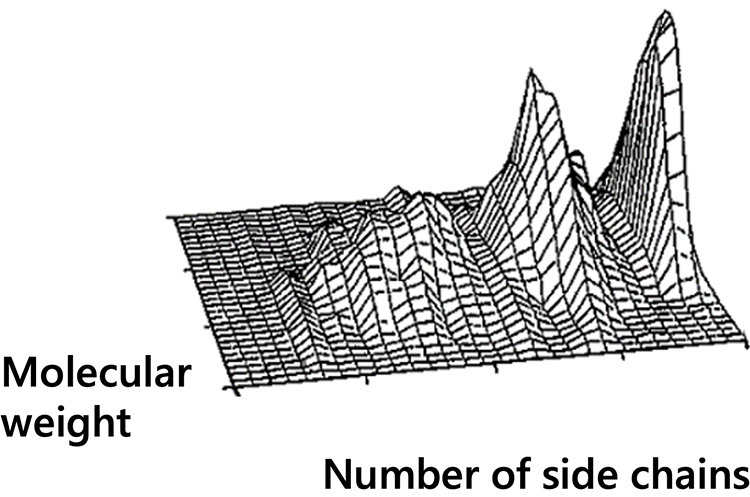

Excellen™ VL has broad chemical composition distribution and also possesses high melting point component.

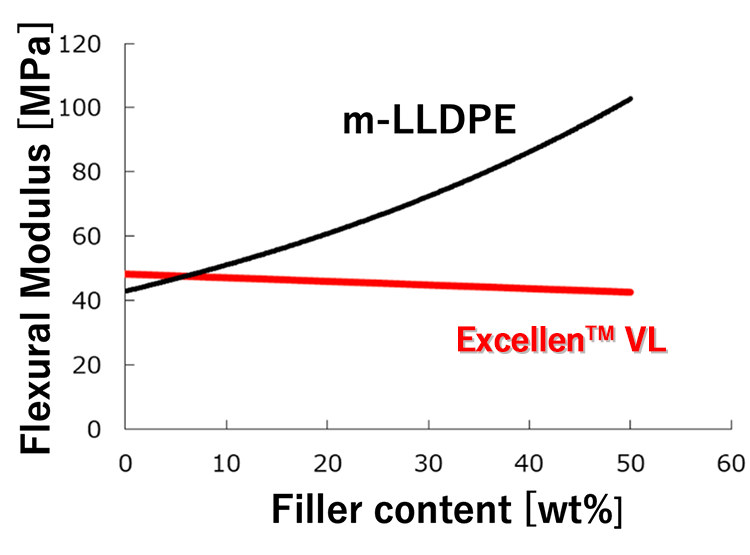

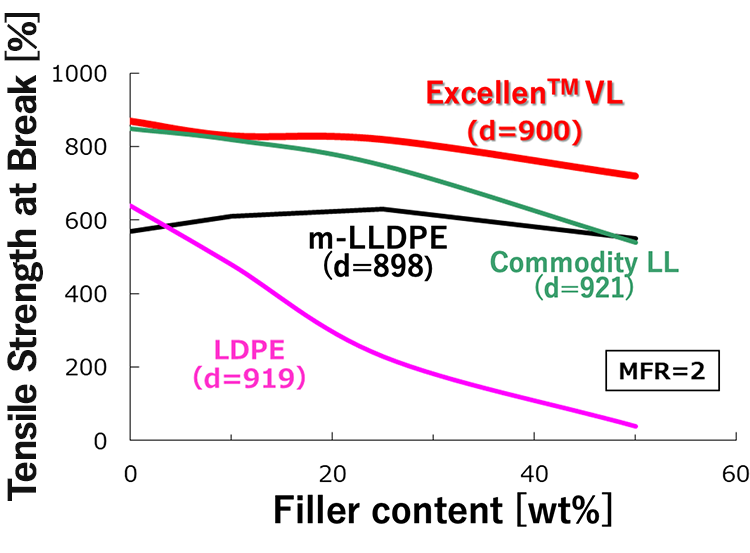

3. Filler acceptability

Excellen™ VL has excellent filler acceptability due to its high content of amorphous phase.

-

Filler: Mg(OH)2

-

Filler: Mg(OH)2

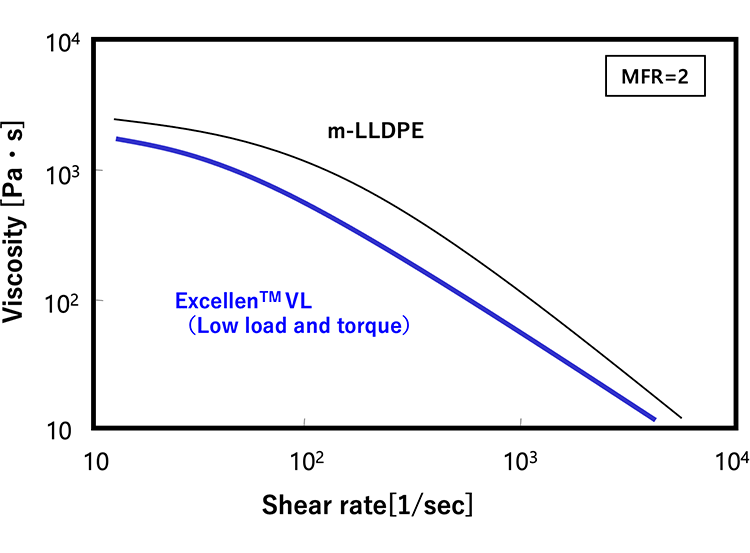

4. Good processability

Excellen™ VL has good processability due to its broad molecular weight distribution.

Features of Excellen™ FX

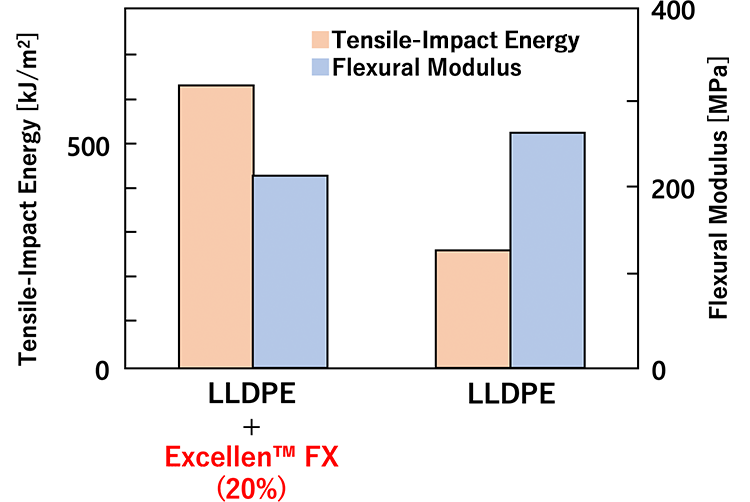

1. Impact resistance

Excellen™ FX is a good modifier for improving the impact resistance of LLDPE due to its flexibility.

2. Pinhole resistance

Excellen™ FX improves pinhole resistance when mixed with LLDPE due to its flexibility and high tensile strength.

| m-LLDPE | m-LLDPE: 70 FX201: 30 |

||

|---|---|---|---|

| MFR | [g/10min] | 4.0 | 3.3 |

| Density | [kg/m3] | 905 | 904 |

| Gelbo flex test [Number of pinholes/450cm2] |

5,000 times | 0 | 0 |

| 10,000 times | 4 | 0 | |

| 20,000 times | 8 | 0 | |

80μm blown film

Measured by Gelbo flex tester

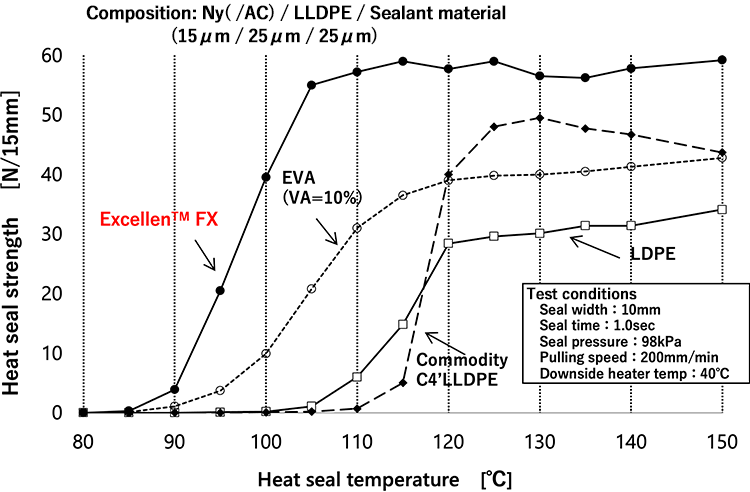

3. Low-temperature sealability

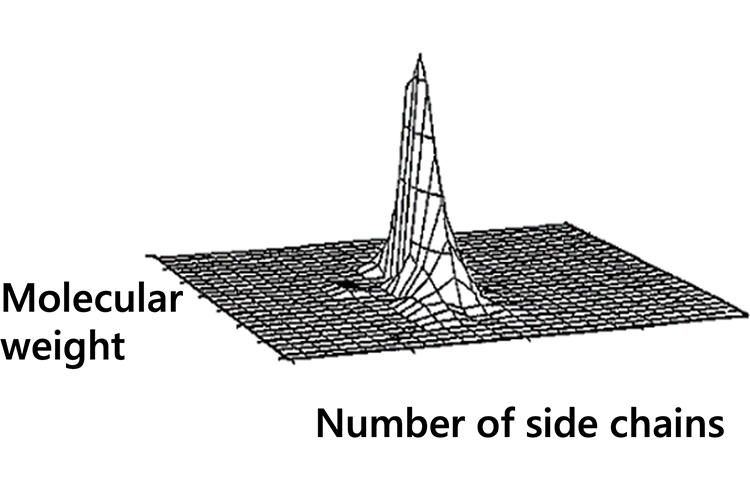

Excellen™ FX shows good low-temperature heat sealing property due to its low melting point and narrow chemical composition distribution.