- PRODUCT

- Gas Barrier Coating Agent (Excevier™)

PRODUCT

Gas Barrier Coating Agent

(Excevier™)

What is Excevier™

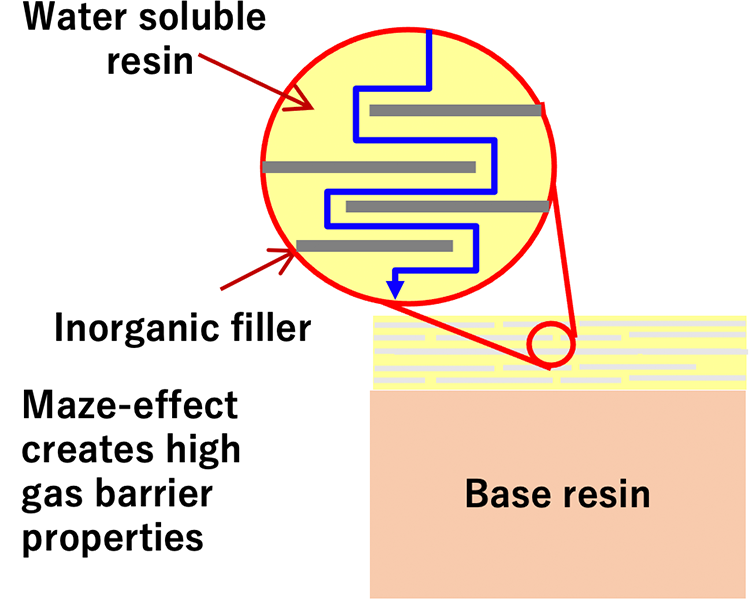

- Organic-inorganic hybrid aqueous coating agent

- Delivers excellent gas-barrier properties achieved by coating then drying

- High aroma retention, solvent resistance and transparency in addition to oxygen and water vapor gas barrier properties

- Wide range of applications, from vacuum molding and stretch blow molding to non-molding use (film or metal)

Grades

| NOH1200 | NOH2200 | ||

|---|---|---|---|

| Liquid physical properties | Solid component concentration (wt%) | 8 | |

| Viscosity* (mPa・s) |

220 | 350 | |

| pH | 4~5 | ||

| Coating film properties** | Oxygen permeability*** (㏄/m2・day・atm) |

3 | 1 |

| Thermal moldability (stretch ratio) |

◎ (~4 times) |

○ (~2 times) |

|

| Characteristics and main usage | High stretch grade Low barrier performance Stretch blow |

Low stretch grade High barrier performance Vacuum molding |

|

* BL-type viscometer (TOKIMEC; Rotor No.1, 12rpm, 30℃)

** base film PET 25μm/AC/Excevier™ (1μm)

*** 23℃×85%RH

The values given are standard values and not to be considered as sales specifications or guaranteed values.

Humidity dependency of oxygen permeability

| Relative humidity(%RH) | ||||

|---|---|---|---|---|

| 50 | 80 | 85 | ||

| Oxygen permeability* (㏄/m2・day・atm) |

NOH1200** | 2 | 3 | 3 |

| NOH2200** | 1 | 1 | 1 | |

| Resin barrier materials (20μm) |

1 | 2 | 5 | |

* 23℃

** base film PET 25μm/AC/Excevier™ (1μm)

The values given are standard values and not to be considered as sales specifications or guaranteed values.

Coating methods

| Type | Methods (examples) |

|---|---|

| Film | Gravure printing |

| Sheet | Gravure printing Dipping, Spray |

| Container, Bottle | Dipping, Spray |

-

Gravure printing

-

Dipping

-

Spray

Application : Vacuum molding container

Coating sheet

Comparison with conventional resin barrier material

-

Oxygen permeability

(cc/m2・day・atm)Before stretch After stretch Excevier™

(1μm)1 2 Resin barrier material

(20μm)1 8 Resin barrier material

(40μm)< 1 > 10 Stretch ratio: 2x

-

Caution

Coating usage

Please prevent from using Excevier™ at innermost or outermost layer of multi layer composition of the container, sheet or film, since it is water soluble material. Use a top layer or perform resin-film dry lamination as shown in the examples(① and ②) below.