- PRODUCT

- EXCELLEN™ for Medical Devices

PRODUCT

EXCELLEN™ for Medical Devices

What is Excellen™ for Medical Devices?

Excellen™ for Medical Devices is a polyolefin formed of a resin composition and additives under strict contamination control according to Japanese Pharmacopoeia. It is compatible with various sterilization methods including gamma ray sterilization.

Careful and strict control of the manufacturing process ensures high quality, and our logistics ensure safe product use.

Lineup

| Types | Features | Applications |

|---|---|---|

| Polypropylene (PP) |

Good compatibility with various sterilization methods; highly flexibile; good processability | IVD, infusion bottles, syringes, prescription bottles, medical procedure instruments, contact lens molds, and many others |

| Low Density Polyethylene (LDPE) |

Highly flexible; good processability | Prescription bottles, eye drop containers, enema containers, infusion bags, buffer film, packing, nozzles, caps, and many others |

| Linear Low Density Polyethylene (VLDPE) |

Softener; impact modifier | Infusion bottles, various parts, and many others |

Grades

1. Polypropylene (PP)

| Polypropylene | S131M2 | FH3711F6 | FH3471M | AR244M | W101M2 | ||

|---|---|---|---|---|---|---|---|

| Item | Test Method | Unit | Random PP | Random PP | Random PP | Random PP | Homo PP |

| MFR | ISO 1133 | g/10min | 2 | 3 | 3 | 30 | 8 |

| Melting Point | ISO 3146 | ℃ | 123 | 138 | 141 | 152 | 164 |

| Density | ISO 1183 | kg/m3 | 896 | 890 | 900 | 895 | 905 |

| Tensile Yield Strength | ISO 527 | MPa | 19 | 20 | 23 | 31 | 37 |

| Tensile Elongation at Break | ISO 527 | % | 500 | 480 | 470 | 520 | 90 |

| Flexural Modulus | JIS K7171 | MPa | 540 | 600 | 750 | 1,300 | 1,800 |

| Charpy Impact Strength | JIS K7111 | kJ/m2 | N.B. | 36 | 12 | 5 | 5 |

| Heat Deflection Temperature | JIS K7191 | ℃ | 57 | 59 | 64 | 84 | 107 |

| Hardness | JIS K7202 | R-scale | 54 | 61 | 76 | 94 | 106 |

| Recommendable Molding Method | Blow | Extrusion, Blow | Injection | ||||

| Features | Highly transparent; highly flexible | Heat resistant; highly transparent; impact resistant; low particles | Heat resistant; highly transparent; radiation resistant | Heat resistant; highly transparent; radiation resistant | Heat resistant; high elastic modulus | ||

- The values above are standard values. They are not to be considered as sales specifications or guaranteed values.

2. Low Density Polyethylene (LDPE)

| Low Density Polyethylene | F101-M | F102-M | F218-M | G201-M | G202-M | G401-M | L705-M | G801-M | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Item | Test Method | Unit | ||||||||

| MFR | JIS K7210-1 *1 | g/10min | 0.3 | 0.4 | 1 | 2 | 1.5 | 4 | 7 | 20 |

| Density | JIS K7112 | kg/m3 | 922 | 922 | 919 | 919 | 919 | 926 | 919 | 919 |

| Tensile Yield Strength | JIS K7161 *2 | MPa | 20 | 22 | 16 | 16 | 17 | 16 | 14 | 13 |

| Tensile Elongation at Break | JIS K7161 *2 | % | 650 | 740 | 700 | 600 | 600 | 550 | 550 | 550 |

| Tensile Modulus | JIS K7161 *2 | MPa | 275 | 265 | 115 | 115 | 115 | 180 | 120 | 125 |

| Flexural Modulus | ASTM D747 | MPa | 225 | 205 | 215 | 185 | 185 | 265 | 165 | 155 |

| Durometer Hardness | JIS K7215 | D | 57 | 54 | 47 | 47 | 48 | 50 | 46 | 45 |

| Environmental Stress Cracking Resistance | ASTM D1693 *3 | hr | > 300 | 9 | 3.5 | 3.5 | 4 | 1 | 1.9 | 0.5 |

| Vicat Softening Temperature | JIS K7206 | ℃ | 100 | 97 | 91 | 91 | 91 | 100 | 86 | 83 |

| Melting Point | JIS K7121 | ℃ | 112 | 112 | 109 | 107 | 108 | 113 | 107 | 106 |

| Brittle Temperature | JIS K7216 | ℃ | < -65 | < -65 | < -65 | < -65 | < -65 | < -65 | < -65 | -35 |

| Example Applications | Buffer film; eye-drop containers | Enema containers | Medicine bottles | Enema containers; medicine bottles | Eye-drop containers | Ointment containers | Eye-drop containers | Enema containers; eye-drop containers | ||

- The values above are standard values. They are not to be considered as sales specification or guaranteed values.

*1 190℃, 21.2N

*2 Test Piece: Type No. 2, 500mm/min

*3 Constant Strain Method, Reagent: IGEPALTM CO-630 10% Solution

3. Linear Low Density Polyethylene (VLDPE)

| Linear Low Density Polyethylene | EUL731-M | ||

|---|---|---|---|

| Item | Test Method | Unit | |

| MFR | JIS K7210-1 *1 | g/10min | 10 |

| Density | JIS K7112 | kg/m3 | 895 |

| Tensile Yield Strength | JIS K7161 *2 | MPa | 9 |

| Tensile Elongation at Break | JIS K7161 *2 | % | 900 |

| Tensile Modulus | JIS K7161 *2 | MPa | - |

| Flexural Modulus | ASTM D747 | MPa | 54 |

| Durometer Hardness | JIS K7215 | D | 37 |

| Environmental Stress Cracking Resistance |

ASTM D1693 *3 | hr | > 2,000 |

| Vicat Softening Temperature | JIS K7206 | ℃ | 52 |

| Melting Point | JIS K7121 | ℃ | 114 |

| Brittle Temperature | JIS K7216 | ℃ | < -75 |

| Example Applications | Modifier for PP | ||

- The values above are standard values. They are not to be considered as sales specification or guaranteed values.

*1 190℃, 21.2N

*2 Test Piece: Type No. 2, 500mm/min

*3 Constant Strain Method, Reagent: IGEPAL™ CO-630 10% Solution

Medical Quality Management

The safety of Excellen™ for Medical Devices is confirmed through a variety of tests that comply with the Japanese law Act on Securing Quality, Efficacy and Safety of Products Including Pharmaceuticals and Medical Devices.

1. Japan Pharmacopoeia Tests

| Ashing Test | |||

|---|---|---|---|

| Residue on Ignition % |

Heavy Metals μg/g |

Pb μg/g |

Cd μg/g |

| ≦ 0.1 | ≦ 20 | ≦ 1 | ≦ 1 |

| Elution Test | ||||||

|---|---|---|---|---|---|---|

| Appearance | Foaming min. |

⊿pH | KMnO4 Reducing Substance ml |

Residue on Evaporation mg |

UV spectrum absorbance | |

| 220-240nm | 241-350nm | |||||

| Limpid and Colorless | PP ≦ 3 PE ≦ 2* |

≦ 1.5 | ≦ 1.0 | ≦ 1.0 | ≦ 0.08 | ≦ 0.05 |

All tests are mainly conducted according to Japanese Pharmacopoeia 17th revision.

(*Foaming test of PE is conducted according to NHI No. 336.)

2. Biological Safety Tests

Biological safety tests were conducted to evaluate criteria that were determined based on contact parts and accumulated contact time.

| Test item | Results | ||

|---|---|---|---|

| G801-M | AR244M | FH3471M | |

| Skin sensitization | No skin sensitization | No skin sensitization | No skin sensitization |

| Pyrogen | Negative | Negative | Negative |

| Acute Toxicity | Not observed | Not observed | Not observed |

| Blood Compatibility; Hemolytic Toxicity | No hemolytic toxicity | No hemolytic toxicity | No hemolytic toxicity |

| Cell Toxicity (V79 Cell) | Not observed | Not observed | Not observed |

| Intracutaneous Reactivity | Negative | Negative | Negative |

- Tests were conducted in accordance with NHI 0301-20.

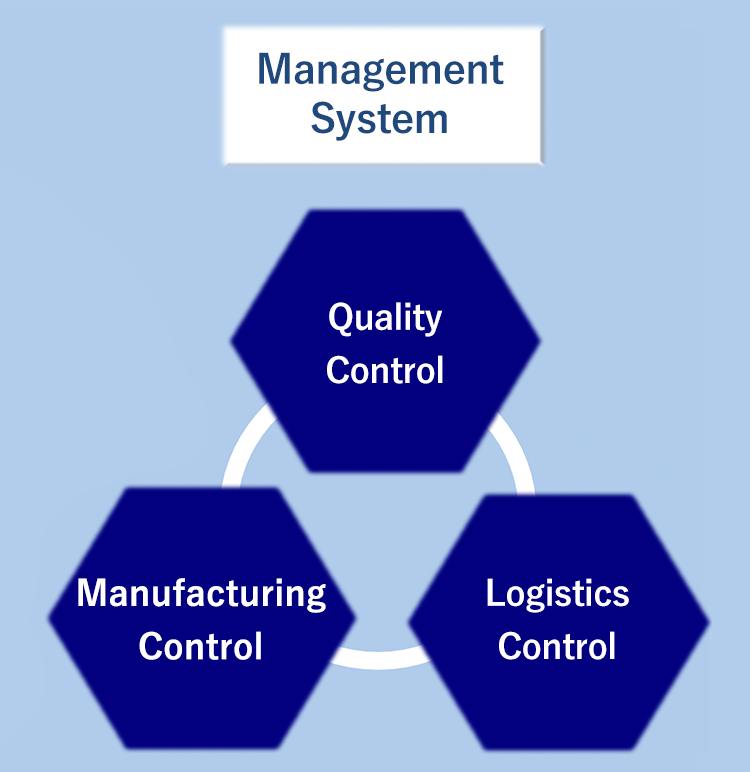

Assuring Manufacturing and Logistics Control

- Thoroughly controlled to prevent contamination during the manufacturing process.

- Reduced risk of contamination from auxiliary materials and environment by using specialized packaging and over-cover

- Dedicated storage area and shipping process

-

Medical PE bag; 25kg

One-way Plastic Pallet (1,400×1,100mm)

-

Medical One-way Flexible Container; 500kg

Running Plastic Pallet (1,100×1,100mm)

Minimum Order Quantity is 1 metric ton.

Medical Policy

Excellen™ for Medical Devices is produced under guidelines specifically designed for the manufacturing process, our quality control, our logistics, and our material handling of products used for medical purposes.

Notice

We must confirm the application for use in advance.

We are also reserve the right to decline sales for applications with very high PL risks. (e.g. implants or the like).