- PRODUCT

- IGETABOND™

PRODUCT

IGETABOND™

Igetabond™

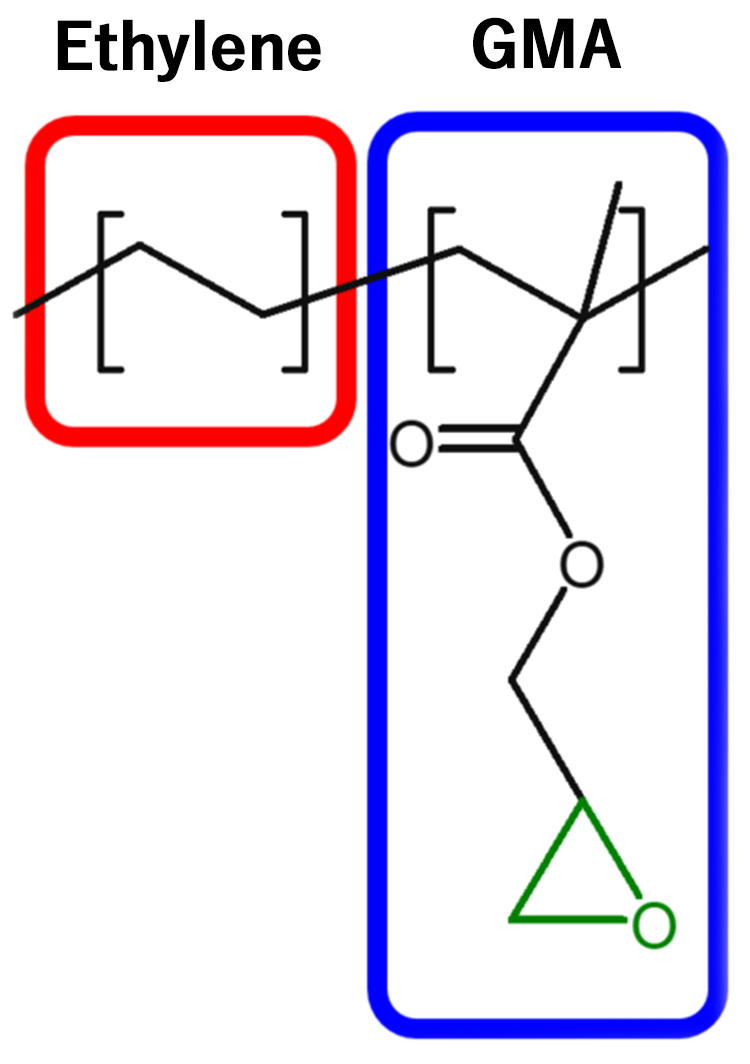

Igetabond™(IB) is an ethylene-glycidyl methacrylate (E-GMA) co-polymer. Igetabond™ exhibits excellent reactivity and adhesion to a wide variety of materials due to its epoxy group.

| Form | Pellet |

|---|---|

| Melting point | 50~105℃ |

| MFR (190℃, 21.2N) | 3–7g/10min (excluding some grades) |

| Glass transition temperature (Tg) | < -25℃ |

| Elongation at break (E) | > 500% |

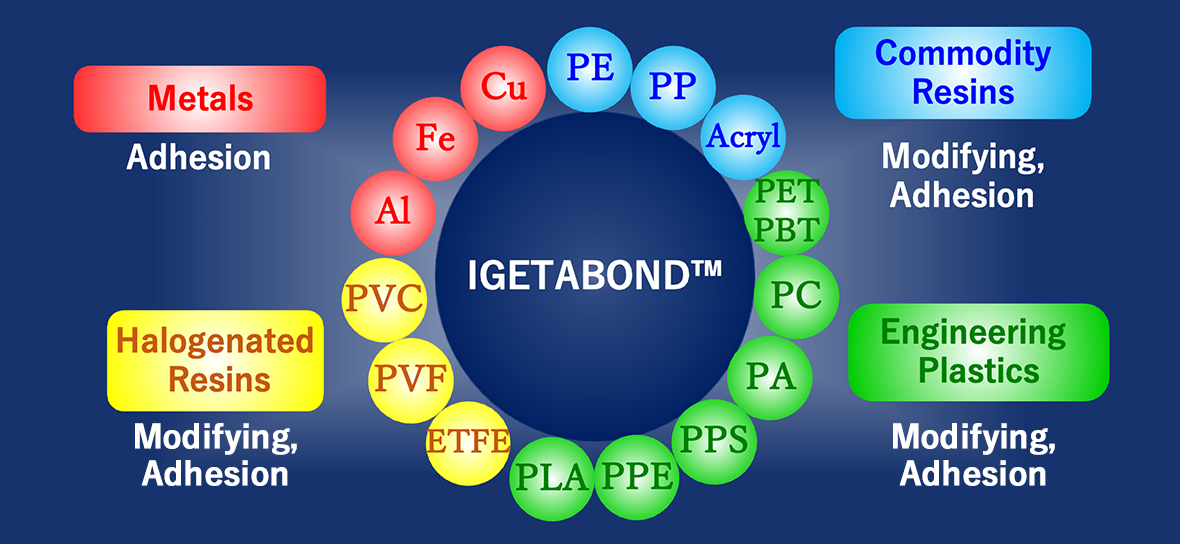

PE: Polyethylene, PP: Polypropylene, Acryl: Polymethyl methacrylate, PET: Polyethylene terephthalate, PBT: Polybutylene terephthalate, PC: Polycarbonate, PA: Polyamide, PPS: Polyphenylene sulfide, PPE: Polyphenylene ether, PLA: Polylactic acid, ETFE: Ethylene-Tetrafluoroethylene Copolymer, PVF: Polyvinyl fluoride, PVC: Polyvinyl chloride, Al: Aluminum, Fe: Iron (stainless steel), Cu: Copper

Grades

| Polymer Type | E-GMA Copolymer | E-GMA-VA Terpolymer | E-GMA-MA Terpolymer | Copolyester Component | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Item | Test Method | Unit | BF-2C | BF-E | BF-30C | CG5001 | BF-2B | BF-7B | BF-7L | BF-7M | VC40 |

| Glycidyl Methacrylate(GMA) Cont. | Sumitomo-Method | wt% | 6 | 12 | 19 | 19 | 12 | 12 | 3 | 6 | - |

| Vinyl Acetate (VA) Cont. | Sumitomo-Method | wt% | - | - | - | - | 5 | 5 | - | - | - |

| Methyl Acrylate (MA) Cont. | Sumitomo-Method | wt% | - | - | - | - | - | - | 27 | 27 | - |

| MFR | JIS K7210-1*1 | g/10min | 3 | 3 | 30 | 380 | 3 | 7 | 7 | 7 | 7 |

| Density | JIS K7112 | kg/m3 | 930 | 940 | 960 | 950 | 950 | 950 | 960 | 960 | 1130 |

| Tensile Strength at Break | ASTM D638*2 | MPa | 18 | 19 | 11 | 4 | 19 | 17 | 4 | 3 | 16 |

| Elongation at Break | ASTM D638*2 | % | 650 | 700 | 730 | 250 | 750 | 750 | 850 | 1000 | 650 |

| Apparent Bending Modulus | ASTM D747 | MPa | 98 | 69 | - | 3 | 39 | 39 | 6 | 4 | 400 |

| Vicat Softening Point | JIS K7206 | ℃ | 83 | 75 | 61 | 45 | 68 | 66 | < 25 | < 25 | 65 |

| Brittle Point | JIS K7216 | ℃ | < -70 | < -70 | - | - | < -70 | < -70 | < -70 | < -70 | < -70 |

| Melting Point | Sumitomo-Method (DSC) | ℃ | 105 | 103 | 96 | 88 | 95 | 95 | 60 | 52 | 95 |

| Glass Transition Temperature (Tg) | Sumitomo-Method (DSC) | ℃ | -26 | -26 | -29 | -27 | -28 | -28 | -33 | -33 | - |

| Moisture Absorption | JIS K6911 | % | < 0.01 | < 0.01 | - | - | < 0.02 | < 0.02 | < 0.05 | < 0.05 | 0.21 |

*1: 190℃, 21.2N;

*2: Type IV specimen at an elongation rate of 200mm/min.

The values given are standard values and not to be considered as sales specifications or guaranteed values.

Features

- High reactivity to a variety of compounds or polymers with functional groups

- High flexibility and ductility

- Excellent adhesion properties to various materials

- Excellent processability by extrusion and injection molding

- Wide range of E-GMA, E-GMA-VA, and E-GMA-MA grades

Applications

1. Polymer modifier

Since Igetabond™ possesses an epoxy group, it is effective in improving impact resistance or inhibiting polymer hydrolysis when alloyed with engineering plastics having a reactive functional group.

(Ex.: PET, PBT, PC, PPS, PES, PPE, and PA)

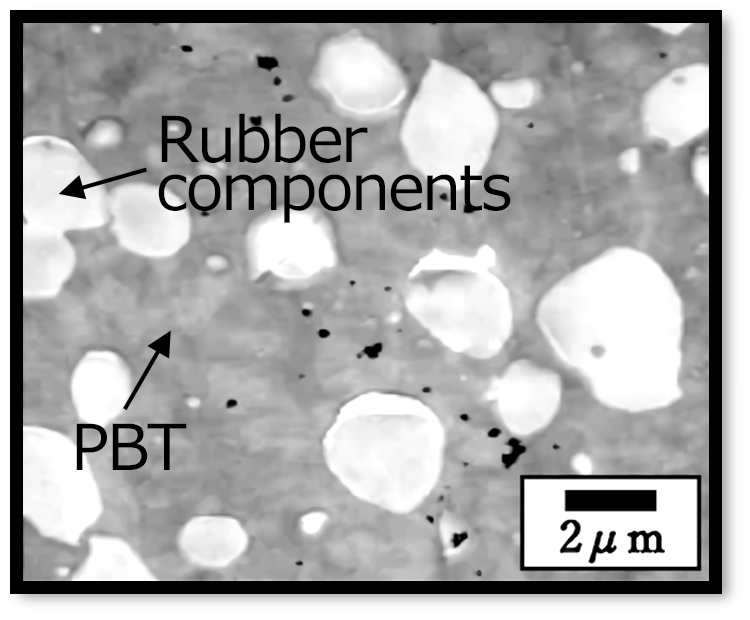

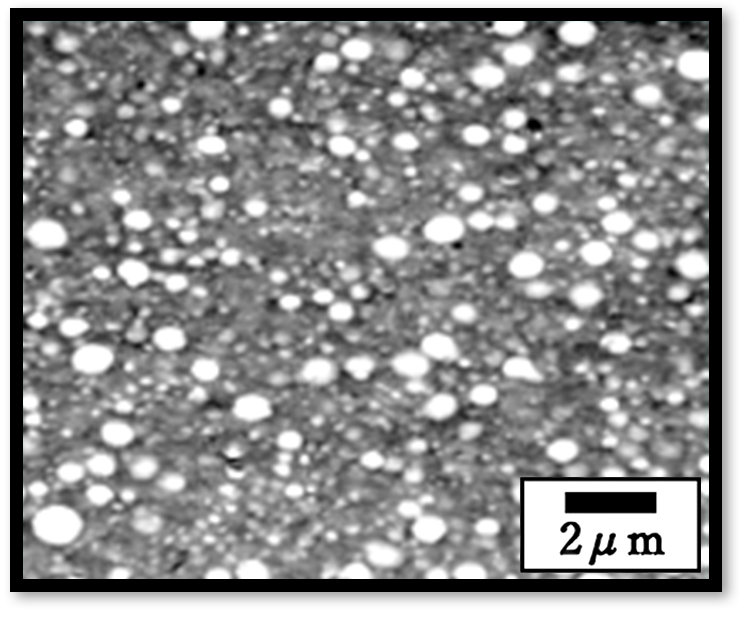

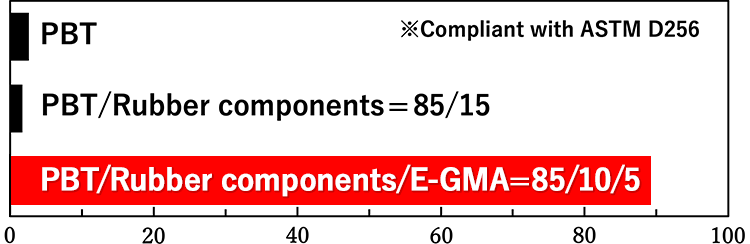

①Modifying PBT (Impact resistance)

E-GMA functions as a compatibilizer for PBT and rubber components and improves the rubber dispersibility in PBT and impact resistance of PBT/rubber composite.

-

PBT/Rubber components

-

PBT/Rubber components/ E-GMA

-

Izod impact strength of notched specimens at 23℃ [kJ/m2]

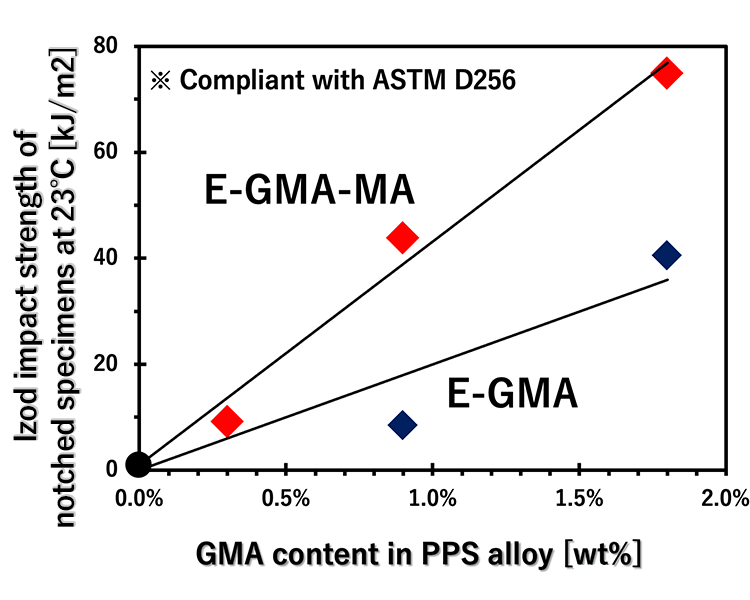

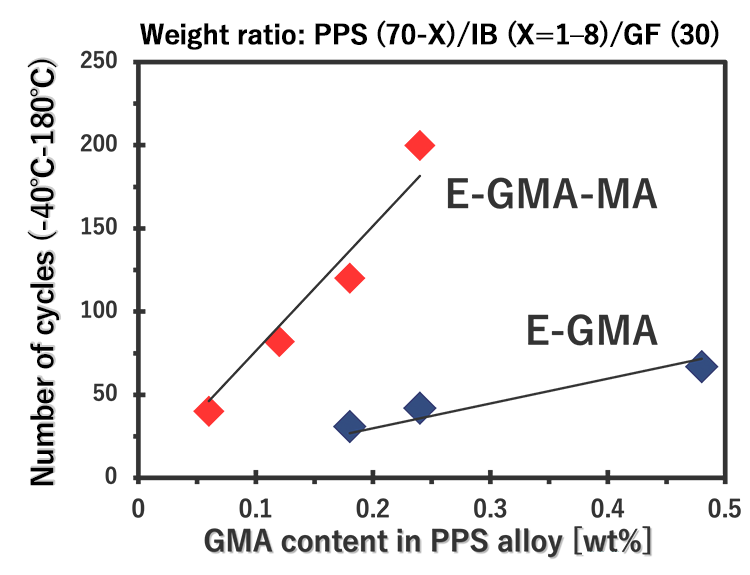

②Modifying PPS (Impact resistance)

E-GMA-MA can improve impact resistance without blending rubber components.

③Modifying PPS (Heat cycle resistance)

Igetabond™ improves resistance to heat cycle.

-

-

<Test condition>

1 cycle :

180℃ 2hrs → -40℃ 2hrs → 180℃Evaluation method :

Counting the number of cycles until cracks emerge in the moldingSample :

Insert-injected molding (metal pin with minimum thickness of 1 mm)

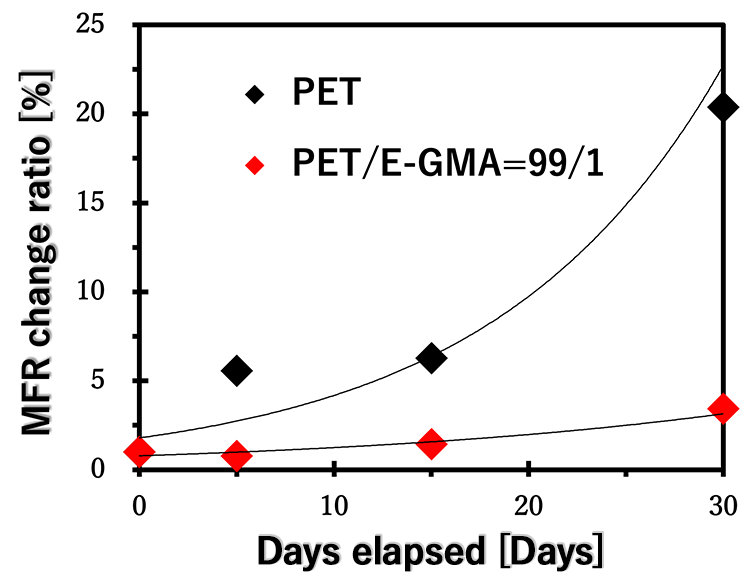

④Modifying PET (Hydrolysis resistance)

Igetabond™ improves the hydrolysis resistance of PET.

-

-

<Test conditions>

Resins were immersed in 80℃ pure water, and MFR was measured after a predetermined number of days.

MFR measurement conditions:

Temperature: 260℃

Load: 21.2N

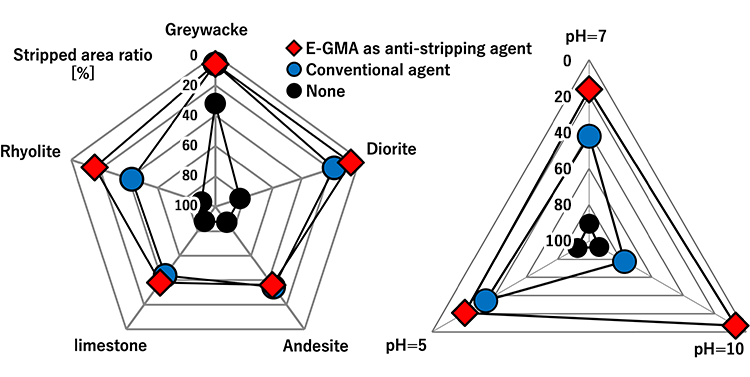

2. Asphalt modifier (Improving of peeling strength to aggregates)

Test method: Test method for Coating and Stripping of Asphalt-Aggregate Mixtures (JPI-5S-27-86)

Test conditions: Sample was immersed in water at 80℃ for 1 week

Test piece: Straight asphalt/SBS/anti-stripping agent=100/4/0.15

Asphalt coating aggregate after 1 week immersed in pH=10 water.

-

No anti-stripping agent

-

With Igetabond™ (E-GMA)

3. Adhesive applications

Thermal bonding properties of Igetabond™ with various materials

Igetabond™ shows good adhesion to various substrates.

*Corona discharge treatment

| Adhesive resin | Base layer (substrate) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Commodity Resins | Engineering Plastics | Fluorocarbon Polymers | Metals | ||||||||||

| LDPE | PP | PS | Soft PVC | PET* | PC | PA | ETFE* | PFA* | SUS | Al | Fe | Cu | |

| BF-E | ◎ | ◎ | 〇 | × | 〇 | ◎ | × | ◎ | 〇 | ◎ | ◎ | 〇 | ◎ |

| BF-7B | ◎ | ◎ | 〇 | △ | 〇 | ◎ | △ | ◎ | 〇 | ◎ | ◎ | 〇 | 〇 |

| VC-40 | 〇 | △ | 〇 | ◎ | ◎ | ◎ | 〇 | 〇 | × | ◎ | ◎ | 〇 | ◎ |

| MAH grafted PE | ◎ | 〇 | × | × | △ | × | ◎ | × | × | ◎ | ◎ | ◎ | × |

| MAH grafted EVA | ◎ | ◎ | × | × | 〇 | × | ◎ | × | × | ◎ | ◎ | ◎ | ◎ |

| EAA copolymer | ◎ | × | × | × | 〇 | × | ◎ | × | × | ◎ | ◎ | ◎ | ◎ |

Substrate/Adhesive resin (50μm)/LDPE (50μm)

LDPE layer was sealed via a heat sealer (190℃, 3kg/cm2, 3sec)

Peeling conditions: 180°angle, 100mm/min speed

Precautions

Notes to prevent Igetabond™ gelation in extruder.

- Prolonged residence of Igetabond™ in a hot extruder can cause gelation due to thermal ring opening of the epoxy group.

When interrupting or stopping the operation of the extruder, make sure to purge the Igetabond™ fully. LDPE with MFR of 3-5 g/10 min is generally used for the purge resin. - Avoid melting or mixing Igetabond™ with polymers having high reactivity to epoxy groups in the extruder. Doing so may cause significant gelation.