- Product Info

- SUMIKAEXCEL PES

- Grade Lineup

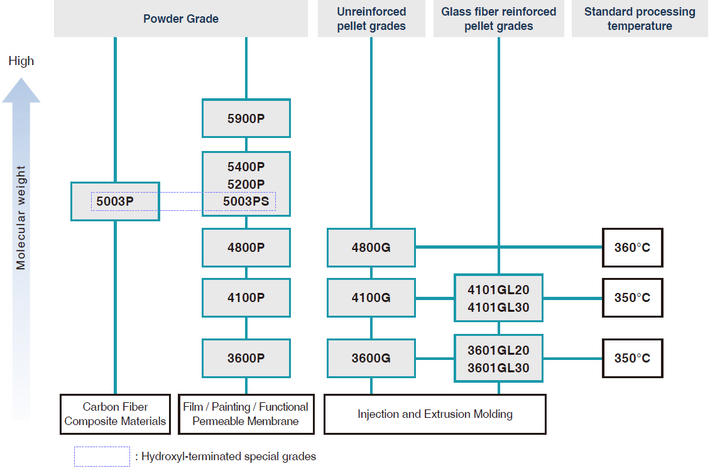

SUMIKAEXCEL PES Grade Lineup

Injection Molding Grade

We offer standard grades consisting of unreinforced and glass fiber reinforced grades, as well as functional grades such as sliding grades, high dimensional accuracy grades, and carbon fiber reinforced grades. The functional grades are sold under SUMIPLOY trademark.

Table 1-2-1 SUMIKAEXCEL and SUMIPLOY injection molding grades

| Grade | Filler | Features | |

|---|---|---|---|

| SUMIKAEXCEL | 3600G | Non-reinforced | High flow for injection molding |

| 4100G | Non-reinforced | Standard for injection molding and extrusion | |

| 4800G | Non-reinforced | High molecular weight for injection molding and extrusion molding | |

| 3601GL20 | 20% Glass Fiber Reinforced | High flow for injection molding | |

| 3601GL30 | 30% Glass Fiber Reinforced | High flow for injection molding | |

| 4101GL20 | 20% Glass Fiber Reinforced | Injection Molding Standards | |

| 4101GL30 | 30% Glass Fiber Reinforced | Injection Molding Standards | |

| ES5340 | 20% Glass Fiber Reinforced | Ultra-high flow for injection molding | |

| SUMIPLOY | E3010 | 40% E101/Fluorine resin reinforced | Non-reinforced, sliding |

| FS2200 | 10% Fluorine Resin Reinforced | Non-reinforced, sliding | |

| GS5620 | 40% Glass Fiber/Fluororesin Reinforced | Sliding, high dimensional accuracy | |

| CS5220 | 20% Carbon Fiber/Fluoroplastic Reinforced | Sliding, high dimensional accuracy | |

| CS5530 | 40% carbon fiber/inorganic filler reinforced | Ultra-high dimensional accuracy | |

| CS5600 | 30% Carbon Fiber Reinforced | High strength | |

| CK3400 | 18% Carbon Fiber Reinforced | PEEK resin based high speed/high load sliding | |

| CK3420 | 30% Carbon Fiber/Fluoroplastic Reinforced | PEEK resin based high speed/high load sliding | |

| CK4600 | 30% Carbon Fiber Reinforced | PEEK resin base, high strength | |

Powder Grade

We offer a variety of grades with different RV (reduced viscosity), which is an indicator of molecular weight, and they can be used according to the application.

Solvents used for SUMIKAEXCEL PES include N-methylpyrrolidone (NMP), dimethylformamide (DMF), dimethylacetamide, Y-butyrolactone, and methylene chloride/1.1.2-trichloroethane = 50/50 (weight ratio).

Table 1-2-2 SUMIKAEXCEL powder grades

| Grade | Reduced Viscosity (RV) *1 |

Applications | ||||||

|---|---|---|---|---|---|---|---|---|

| Compound | Paint | Functional permeable membrane | Glue | Film | Epoxy toughener | Carbon Fiber Composites (for aircraft applications) |

||

| 3600P | 0.36 | ◎ | - | - | - | - | - | - |

| 4100P | 0.41 | ◎ | ◎ | - | ○ | ○ | - | - |

| 4800P | 0.48 | ○ | ○ | ○ | ○ | - | - | - |

| 5003PS *2 | 0.50 | - | ◎ | - | ◎ | - | ◎ | - |

| 5200P | 0.52 | - | - | ○ | - | - | - | - |

| 5900P | 0.59 | - | - | ◎ | - | - | - | - |

| 7600P | 0.76 | - | - | ◎ | - | - | - | - |

| 5003P *2 | 0.50 | - | - | - | - | - | - | ◎ |

*1 Reduced viscosity is measured in a 1% solution of dimethylformamide (DMF).

*2 It has a high terminal hydroxyl group count of 0.6 to 1.4 per 100 polymer repeat units.

Figure 1-2-1 SUMIKAEXCEL PES grade lineup