- Product Info

- SUMIKASUPER LCP

- Molding processability of LCP

Molding processability of SUMIKASUPER LCP

Apparent Melt Viscosity

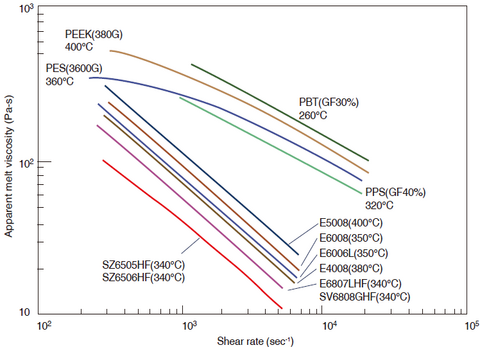

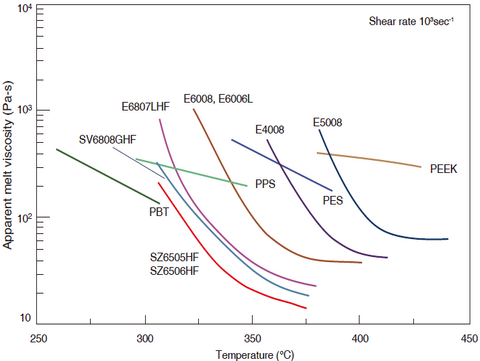

The shear rate dependency and temperature dependency of the apparent melt viscosity of SUMIKASUPER LCP are shown below. Compared to other engineering plastics, the apparent melt viscosity of SUMIKASUPER LCP is significantly affected by both shear rate and temperature, so its molding processability changes significantly depending on the injection speed, cylinder temperature, and shear heat during injection molding. SUMIKASUPER LCP has low viscosity and high shear rate dependency, so even if the injection speed is increased, the pressure does not increase easily, making high-speed injection molding possible. Under appropriate injection molding conditions, it exhibits extremely low viscosity, making it possible to fill thin-walled products and products with complex shapes. However, it is necessary to manage the injection speed and cylinder temperature, and check changes in shear force due to wear, etc.

Figure 4-2-1 Shear rate dependence of apparent melt viscosity

Figure 4-2-2 Temperature dependence of apparent melt viscosity

Thin wall flowability

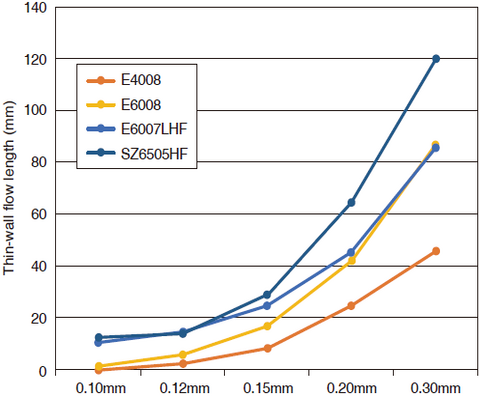

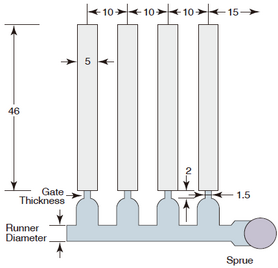

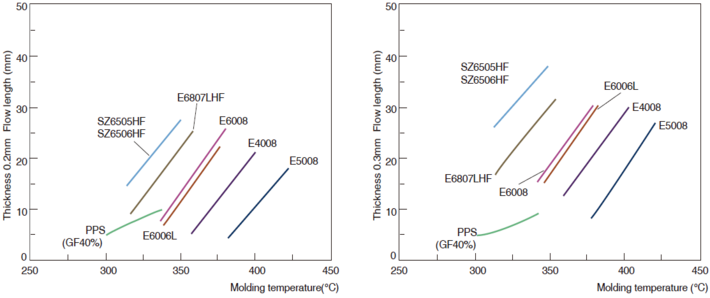

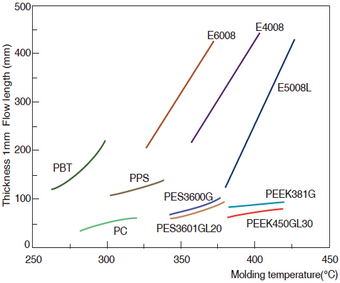

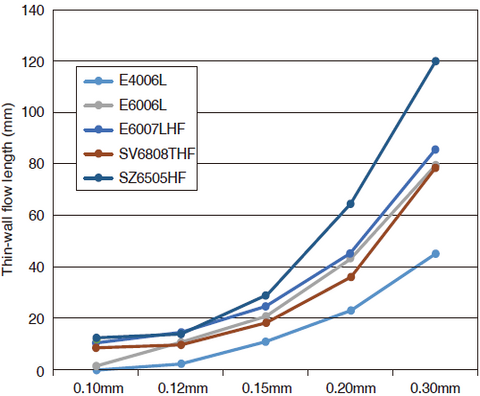

SUMIKASUPER LCP has excellent thin-wall fluidity compared to other engineering plastics. Figure 4-2-4 shows the thin-wall fluidity (thickness 0.2, 0.3 mm) of each grade measured using the mold shown in Figure 4-2-3, and Figure 4-2-5 shows the bar flow length at a thickness of 1 mm.

Figure 4-2-3 Thin-wall flow length measurement mold (unit: mm)

| Product thickness: | 0.3mm |

| Runner: | 4.0mmφ |

| gate: | 0.3t×1.5w×2.0L |

| Flow length is the average of 4 cavities | |

| Product thickness: | 0.2mm |

| Runner: | 3.0mmφ |

| gate: | 0.2t×1.5w×2.0L |

| Flow length is the average of 4 cavities | |

| Forming machine: | Nissei Plastics PS10E1ASE |

| Injection pressure: | 0.2mm thickness: 90MPa 0.3mm thickness: 60MPa |

| Injection speed: | 0.2mm thickness: 95% 0.3mm thickness: 60% |

| Mold temperature: | 130℃ |

Figure 4-2-4 Thin-walled fluidity

Figure 4-2-5 Fluidity of various engineering plastics at 1mm thickness

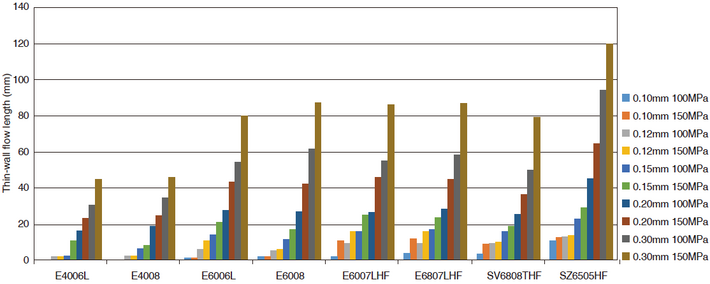

Thin wall flow length

Since the thin-wall flow length of SUMIKASUPER LCP depends on molding conditions and shape, it is possible to compare the relative fluidity of the resin when the molding conditions are constant. The flow length of SUMIKASUPER LCP's thin-wall fluidity is shown below when the injection pressure is changed. SUMIKASUPER LCP has high fluidity even with a test piece thickness of 0.1 mm, and has a wide range of molding conditions, making it suitable for a variety of shapes.

Thin wall fluidity measurement conditions (0.10mm, 0.12mm, 0.15mm, 0.20mm, 0.30mm)

- Injection molding machine: ROBOSHOT S-2000i30B (FANUC)

- Resin temperature: standard molding temperature

- Mold temperature: 120˚C

- Injection speed: 200mm/sec

Figure 4-2-6 Thin-wall flow length measurement mold

Figure 4-2-7 Thin-wall flow length

Figure 4-2-8 Dependence of thin-wall flow length on thickness 1

Figure 4-2-9 Dependence of thin-wall flow length on thickness 2